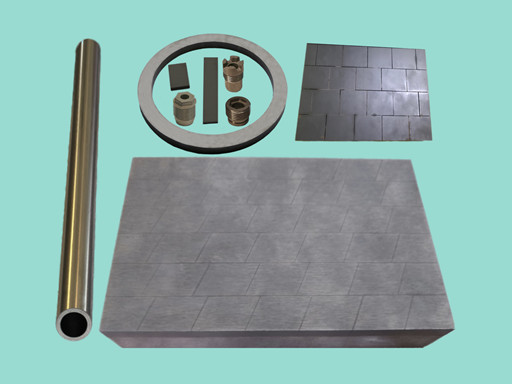

Binderless 99.9% Pure WC Tungsten Cemented Carbide Hardmetal

Super Wear and Severe Corrosion Parts

Cemented Carbide Nozzle Hardmetal Seal Ring

1. AMTmetalTech Binderless 99.9% Pure WC Tungsten Cemented Carbide Hardmetal Super Wear and Severe Corrosion Parts Description

AMTmetalTech produces high quality Binderless 99.9% Pure WC Tungsten Cemented Carbide AMT-PWC Parts from Nanocrystalline tungsten carbide raw powder by advanced powder metallurgy process and strict quality control system at Super High Hardness.

Type | Composition | Density | Hardness HV | Hardness HRA | Bend Strength |

AMT-PWC | WC≥99.9% | ≥15.4g/Cm3 | 2700-2900 | ≥95 | ≥120KSI |

2. MTmetalTech Binderless 99.9% Pure WC Tungsten Cemented Carbide Hardmetal Super Wear and Severe Corrosion Parts Features

AMTmetalTech 99.9% Pure WC Tungsten Cemented Carbide Hardmetal Part without Cobalt or Nickel binder has much higher Wear or Abrasion Resistance and much Longer service life than conventional Tungsten Cemented Carbide Hardmetal with Cobalt Binder or Alumina and Boron Carbide Part, which significantly reduces equipment downtime, resulting in significant economic benefits.

AMTmetalTech 99.9% Pure WC Tungsten Cemented Carbide Hardmetal Part without Cobalt or Nickel binder has Excellent Resistance to Nitric Acid HNO3, Chloric Acid HCl, Sulfuric Acid H2SO4, Acetic Acid C2H4O2, Alkali OH etc.

Media | Nitric Acid | Chloric Acid HCl | Sulfuric Acid | Acetic Acid C2H4O2 | Alkali | Hydrofluoric Acid HF |

AMT-PWC Corrosion Resistance | Excellent | Excellent | Excellent | Excellent | Excellent | Meltable |

AMTmetalTech Binderless Tungsten Carbide Optical Glass Die or Mold has higher oxidation resistance and no sticking to Optical Glass at high temperature without Contamination.

3. AMTmetalTech Binderless 99.9% Pure WC Tungsten Cemented Carbide Hardmetal Super Wear and Severe Corrosion Parts Applications

AMTmetalTech Binderless 99.9% Pure WC Tungsten Cemented Carbide Hardmetal can be widely used to make Super Wear Corrosion Resistant parts under extreme conditions such as high pressure Industrial Nozzles including abrasive Waterjet Nozzles, Sandblasting Nozzles, Spray Drying Nozzles, Centrifugal Nozzles, Seal Rings or Gaskets, Precision Dies or Optic Molds, Valve Core Balls and Seats, Abrasion Sleeves, Magnetron Sputtering Targets, Milling Balls, Stirring Bars etc. We are looking forward to work with Top Quality Customers to develop Competitive more applications for Binderless Pure WC Tungsten Cemented Carbide Parts in more fields.

Hardmetal Valve Ball and Seat Tungsten Carbide Sleeves Cemented Carbide Valve Core Tungsten Carbide Target

Regarding Impact Resist WC-Co Tungsten Carbide with Cobalt binder Hardmetal Wear Parts, please visit https://www.AMTmetalTech.com/PatentProducts/hardmetal_clad.html for more information.

Please send us email about Atomized or Spherical Densified Additive Manufacturing Titanium or Aluminum or Copper AM / 3D Printing / MIM or PM Molding / Soft Magnet Carbonyl Iron Powder, 3D Printed Part, Self-fluxing Nickel Alloy NiCrBSi / NiBSi / Hastelloy / Inconel / Stellite / MCrAlY / NiCrCoAlY / Stainless Steel 316L / 17-4 PH / Bronze or Agglomerated Sintered WC / Chrome Carbide Nickel Chrome Cr3C2-NiCr / Molybdenum Powder for HVAF / HVOF / Flame / Plasma ID or Flash Carbide thermal spraying and Laser Cladding or PTA Clad Tube, Binderless Tungsten Carbide / Titanium Carbide TiC Cemented Hardmetal Wear Part / Seal Ring / Nozzle / Ball Valve etc.