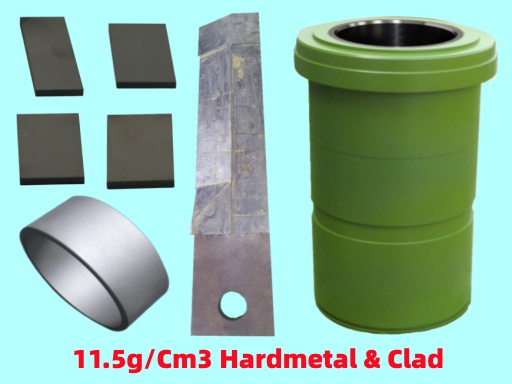

Tungsten Cemented Carbide Hardmetal Crush Bar, Light Tile

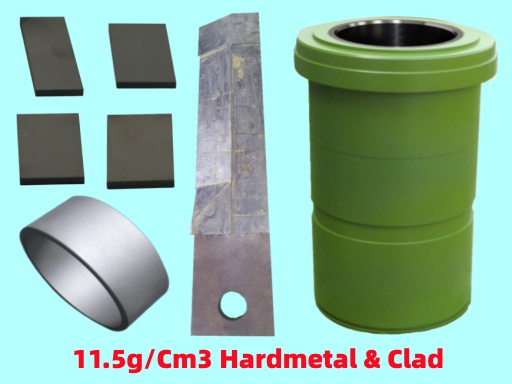

& Braze Clad Patent Quick Assembly Plates, Tubes, Blades

VSI Tungsten Carbide Crush Bars Hardmetal Roller, Button, Disc Cutter Tungsten Carbide Crush Jaw Plate

Seal Ring, Screw Head, Sieve Mesh Tungsten Carbide Tube, Plate Scraper Knife, Valve, Die, Mould

1. AMTmetalTech Tungsten Cemented Carbide Hardmetal Crush Bar, Light Tile & Braze Clad Patent Design Quick Assembly Plates, Tubes, Blades

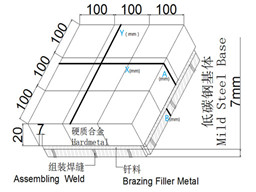

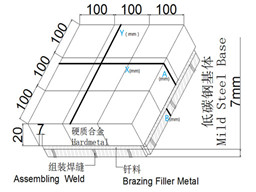

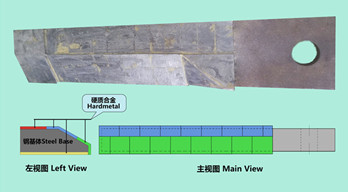

AMTmetalTech Tungsten Cemented Carbide Hardmetal Crush Bar, Light Tile patent design Quick Assembly Clad Plate is made up of the Tungsten Cemented Carbide Tile braze bonded with steel base, which makes the Tungsten Cemented Carbide clad wear plate or Brick Mold enough strength and abrasion resistance.

Typical Dimension: Length X300 * Width Y300mm; Tungsten Cemented Carbide Hardmetal Tile Thickness: A16mm. Mild Steel Base Thickness: B7mm.

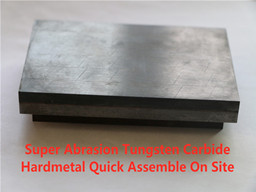

AMTmetalTech Super Abrasion or Wear Resist Tungsten Cemented Carbide Hardmetal Crush Bar, Tile Braze Clad patent design Quick Assembly Plate are for Mining or Cement Industries, Brick Mold, Stirring Slurry Blade etc.

2. AMTmetalTech Super Abrasion or Wear Resist Tungsten Cemented Carbide Hardmetal Crush Bar, Patent Design Rings Connected Clad Mud Pump Liners / Sleeves / Tubes

AMTmetalTech Super Abrasion or Wear Resist Tungsten Carbide Cemented Hardmetal Crush Bar, Patent Design Rings Connected Clad Mud Pump Liner is assembled from Hardmetal Precision Rings Clad inside the steel tube and results in high reliability. The life time can be more than 4 times of the Alumina.

Mud Pump Liner Material | High Chrome Cast Iron | Alumina | Ytteria Stablized Zirconia | Tungsten Carbide Hardmetal |

Life Time | Nearly Half Month | Nearly Half Year | Nearly One Year | More Than 2 Years |

Life Time | A- | A+ | AA+ | AAAAA |

Price | A- | A+ | AA+ | AAAAA |

3. AMTmetalTech Tungsten Cemented Carbide Crush Bar or Light Tile with Titanium Carbide Cemented Light Hardmetal Chemical Composition and Properties

Types | Composition (%) | Density, g/Cm3 | Hardness, HRA | Bend Strength, N/mm2 |

AMYG6 | Co: 5.8-6.2, WC Balance | ≥14.6 | ≥91 | ≥2150 |

AMYG8 | Co: 7.8-8.2, WC Balance | ≥14.5 | ≥90 | ≥2250 |

WTC115 | TiC 5-10%, WC-Co Balance | 11.2-11.8 | ≥90 | ≥1500 |

AMYG11 | Co: 10.8-11.2, WC Balance | ≥14.1 | ≥88 | ≥2300 |

AMYG15 | Co: 14.8-15.2, WC Balance | ≥13.9 | ≥85 | ≥2500 |

AMTmetalTech Unique Quality World Low Price Tungsten Cemented Carbide Crush Bar or Light Tile with Titanium Carbide Hardmetal WTC115 tiles are about 30% lower volume price for both lower weight price and lower density than WC-6Co or WC-8Co with similar super abrasion resistance.

Please send us email to export@AMTmetalTech.com about HDH Hydride-dehydride Titanium Ti64 Powder Sintered Forging Superior than HIP Hot Isostatic Pressing, Gas or Water Atomized Additive Manufacturing Powder Bed Fusion / MIM / Binder Jet 3D Printing Cobalt / Vehicle or Car Part, Nickel Aluminum Alloy NiAlMo Catalyst / Inconel In625 / Stellite / MCrAlY / CoNiCrAlY / NiCoCrAlY / Ti 6Al 4V / Duplex Stainless Steel & 316L or Agglomerated Sintered WC-10Co-4Cr / WC-12Co / Cr3C2-NiCr / Molybdenum Spherical Powder for HVAF / HVOF Thermal or Cold Spraying and Speed Laser Cladding or PTA Clad Weld Overlay Elbow, FerroTiC for Brake Disc, Tungsten Carbide Brazing Rope, Hafnium Wires / Rods for Plasma Cutting from Crystal Iodide Hafnium Bar, Tantalum Ta & Niobium Nb for Alloy Melting, Amorphous Fine Powder Tube Inside ID Spraying replacing Chrome Plating for severe Erosion Cavitation high temperature abrasion resist of Cylinders / Pistons / Roller / Screw Rotors / Valve / Stirrer Blade / Hydro Turbine Runner; Hardmetal Cemented Crush Bar or Clad Mud Pump Liner / Pipe / Sleeve / Glass Mold / Tile / Super Wear Plate; PDC Diffusion Bonding, Diamond Bearing etc.