Agglomerated Sintered Tungsten Carbide WC-Co, Chrome Carbide Cr3C2-NiCr,

Mo Molybdenum Fine Powders for HVOF / HVAF / Plasma Thermal Spraying

1. AMTmetalTech Top Quality World Low Price Agglomerated Sintered Tungsten Carbide WC-Co, Chrome Carbide Cr3C2-NiCr Cemented Hardmetal, Mo Molybdenum Fine Powders

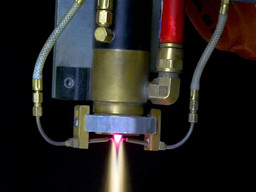

AMTmetalTech as the World Metallurgy Leader of Severe Erosion and Super Abrasion Resist, makes the Top Quality World Low Price Tungsten Carbide or Chrome Carbide Cemented Hardmetal or Mo Molybdenum Powders for HVOF / HVAF / Plasma thermal spraying all from virgin raw material, with more than 24 hours milling to be very homogeneous mixed and then Spray-dried to be very round powders, Vacuum sintered to be controlled hall density, Supersonic sieved and Gas classified to be very consistent particle sizes, to make China, Germany, USA and Japan Customers getting satisfied coating for over 23 years.

AMTmetalTech Top Quality World Low Price Agglomerated Sintered Tungsten Carbide Hardmetal Fine Thermal Spraying Powders grain size can be down to 0.5um. The fine size cut can be good for Tube inside coating including Crystallizers of Continuous Casting. AMTmetalTech is pleased to answer your any Metallurgy questions free of charge during thermal spraying. Please send us your inquiry if you required is not in the following table.

2.1 Top Quality World Low Price Tungsten Carbide Hardmetal Fine Powders Specifications

Name | Powder Type | Particle size | Reference Products | Properties/Applications | ||

Metco | Praxair | Starck | ||||

AM86104-0520 | WC-10Co-4Cr | 5-20um | WOKA | 558.052 | ●Excellent Flowability ●Suitable for Paper Rolls, Gate and Ball Valves, Hydraulic Cylinders etc. | |

AM86104-0530 | WC-10Co-4Cr | 5-30um | WOKA | WC731-6 | 556.059 | |

AM86104-1038 | WC-10Co-4Cr | 10-38um | WOKA 3655 | 1350VF | 557.072 | |

AM86104-1545 | WC-10Co-4Cr | 15-45um | WOKA 3652 | 1350VM | 557.074 | |

AM86104-2053 | WC-10Co-4Cr | 20-53um | WOKA 3651 | 558.088 | ||

AM8812-0520 | WC-12Co | 5-20um | WOKA | ●Excellent Flowability ●High resistance to Abrasion, Erosion and Sliding Wear ●Temperature up to 500℃ ●Suitable for Paper Mill Rolls, Pump Parts, OilField Apparatus, Wire Drawing Equipments, Fan and Compressor Blades, Machine Parts etc. | ||

AM8812-0530 | WC-12Co | 5-30um | WOKA | WC727-6 | 518.059 | |

AM8812-1038 | WC-12Co | 10-38um | WOKA 3105, 3104 | 1342VF | 518.072 519.072 | |

AM8812-2053 | WC-12Co | 15-45um | WOKA 3102, 3103 | 1342VM | 518.074 | |

AM8812-1546 | WC-12Co | 20-53um | WOKA 3101 | 518.088 519.088 | ||

AM8317-1038 | WC-17Co | 5-30um | WOKA 3204 | WC729-5 | 526.059 | ●High Toughness and Ductility, High Fretting resistance ●Not for wet corrosion environments ●Temperature up to 500℃ ●Suitable for Crushing Rolls, Extrusion Dies etc. |

AM8317-0531 | WC-17Co | 10-38um | WOKA 3205 | 1343VF | 526.062 | |

AM8317-1545 | WC-17Co | 15-45um | WOKA 3202, 3203 | 1343VM | 526.074 | |

AM8812N-0530 | WC-12Ni | 5-30um | WOKA 3408, 3404 | 547.059 | ●Good Resist to hammers, fretting, abrasion and sliding wear ●More corrosion-resistant and tougher than WC-Co, but lower hardness ●Temperature up to 500℃ | |

AM8812N-1545 | WC-12Ni | 15-45um | WOKA 3402, 3403 | 1310VF | 547.074 | |

AM8812N-2053 | WC-12Ni | 20-53um | WOKA 3401 | 1310VM | 547.088 | |

AM73207-1545 | WC-20Cr3C2-7Ni | 15-45um | WOKA 3702 | 555.074 | ●Temperature up to 750℃ ●Higher Oxidation and Corrosion Resist than WC-Ni | |

2.2 AMTmetalTech Top Quality World Low Price Tungsten Carbide Hardmetal Powders Application

AMTmetalTech Top Quality World Low Price Hardmetal Powders are widely for producing super Abrasive or Wear, Erosion Resistant coatings by HVOF or HVAF, Plasma Thermal Spraying, which for Turbine Blades, Wire Drawing Equipment, Fans and Compressor Blades, Pumps, Valves, Pistons, Paper Rolls etc. in Aerospace, Petroleum, Metallurgy, Machinery, Transportation, Power, Chemical industries.

HVOF Spraying Screw Rotors Thermal Spraying Cylinders HVAF Spraying Valve Balls

Thermal Spraying Pistons Thermal Spraying Rollers Wire Drawing Cones

3.1 AMTmetalTech Top Quality World Low Price Agglomerated Sintered Chrome Carbide Cr3C2-NiCr Powders for Thermal Spraying Character and Applications

AMTmetalTech Top Quality World Low Price Chrome Carbide Nickel Chrome Cr3C2-NiCr Powders are half density as Tungsten Carbide, for producing High Temperature Erosion and Abrasion resist coatings by HVOF / HVAF / Plasma Thermal Spraying, which for Gas Valves, Furnace Bottom Rolls, Turbine Shaft and Housing, Boiler Superheater Tube etc. in Aerospace, Metallurgical, Power Plant industries.

Boiler Superheater Tube Thermal Spraying Turbine Furnace Bottom Roll

3.2 AMTmetalTech Top Quality World Low Price Chrome Carbide Cr3C2-NiCr Powders Specifications

Name | Powder Type | Particle Size | Reference Products | Properties/Applications | ||

Metco | Praxair | AMPERIT | ||||

AM7525-0525 | Cr3C2-25NiCr | 5-25um | WOKA 7210 | *Excellent for High Temperature Cavitation, Abrasion and Sliding Wear resist *Very Good Hot Gas and Corrosion resist *Used Temperature up to 870℃ *Suitable for Valve Stems, Trubine, Fuel Rod Mandrels etc. | ||

AM7525-1038 | Cr3C2-25NiCr | 10-38um | WOKA 7205, 7204 | 1375VF | 584.072 | |

AM7525-1545 | Cr3C2-25NiCr | 15-45um | WOKA 7202, 7203 | 1375VM | 588.074 584.054 | |

AM7525-2053 | Cr3C2-25NiCr | 20-53um | WOKA 7201, 7207 | 588.088 | ||

AM7525-0545 | Cr3C2-25NiCr | 5-45um, Blend | Amdry 367, Metco 81VF-NS | 585.003 | ||

AM8020-1038 | Cr3C2-20NiCr | 10-38um | WOKA 7105, 7104 | |||

AM8020-1545 | Cr3C2-20NiCr | 15-45um | WOKA 7102 | CRC-351 | 586.1 586.054 | |

4.1 AMTmetalTech Top Quality World Low Price Agglomerated Sintered or Plasma Densified Molybdenum Powders for Thermal or Cold Spraying and Cored Wire main Specifications

Name | Powder Type | Particle Size | Reference Products | Properties/Applications | ||

Metco | Praxair | AMPERIT | ||||

AMMoAS2053 | Mo 99.5 Agglomerated Sintered | 20-53um | WOKA 4063 | 105.074 | ●Good Heat Conduct, Low Expansion, Self-bonding to Metals ●Natural Lubricity and High Hardness ●Good Wear, Heat Impact and Liquid Metal Resist ●Adhesive and Electric Arc Erosion Resist ●Oxidizing Temperature up to 320℃ ●Suitable for Plasma Spraying Electrodes, Valves, Gears, Piston Rings, Pump and Axis Parts etc. | |

AMMoAS4590 | Mo 99.5 Agglomerated Sintered | 45-90um | Mo-130-1 | 105.002 | ||

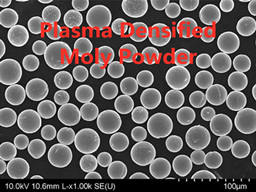

AMMoPD1545 | Mo 99.5 Plasma Densified | 15-45um | ||||

AMMoPD4590 | Mo 99.5 Plasma Densified | 45-90um | Amdry 313X | MO-102 | ||

AMMoSC1563 | Mo 99.0 Sintered Crushed | 15-63um | 106.062 | |||

AMMoSC3890 | Mo 99.0 Sintered Crushed | 38-90um | WOKA 63NS | 106.002 | ||

AMMoB | Mo-25(Ni-17Cr-3.5B-4Si-4Fe) | Blend | Amdry 1371 | AI-1054 | 119.075 | |

AMTmetalTech is no way affiliated with the original equipment manufacturers (OEM)mentioned. All trademark listed herein are not of OEM's origin. References to the OEM'spart numbers are for your convenience only

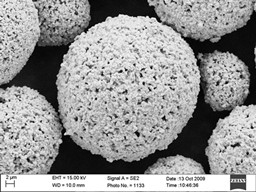

4.2 AMTmetalTech Top Quality World Low Price Agglomerated Sintered or Plasma Densified Molybdenum Powders for Thermal or Cold Spraying and Cored Wire Characterand Applications

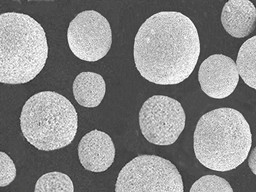

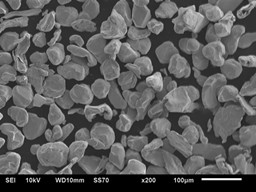

AMTmetalTech Agglomerated Sintered Molybdenum Powders have good Sphericity. AMTmetalTech Sintered and Crushed Molybdenum Powders have good controlled Particle Shape. AMTmetalTech Plasma Densified Molybdenum Powder has very good sphericity and high density. All AMTmetalTech Molybdenum Powders for Plasma thermal spraying are made from fine virgin raw material, have good flow ability and consistent sizes. The Philosophy of AMTmetalTech is Honest and World Top Quality, Quickest Delivery and Most Competitive Pricing.

AMTmetalTech Top Quality Molybdenum Plasma Spraying Powders are widely used for Plasma Spraying the Self Lubricated and Wear Resist, Heat Conduct and Low Expansion, Heat Impact and Liquid Metal Resist, Adhesive and Arc Erosion Resist parts in Auto, Airplane, Metallurgical and Power industries etc.

Molybdenum Coated Piston Rings Molybdenum Coated Electrodes Molybdenum Coated Gears

5. AMTmetalTech Top Quality World Low Price Agglomerated Sintered Tungsten Carbide WC-Co, Chrome Carbide Cr3C2-NiCr, Mo Molybdenum Thermal Spraying Powders Packaging

The standard packaging is by plastic bottle per 5/2.5kg. We can do the other packaging according to the customer requirements.

Please send us email about Atomized Additive Manufacturing AM / Binder Jet Printing / High Speed Steel MIM Powder / 3D Printed Part, Self-fluxing or Spray Fuse Nickel Alloy NiBSi / Inconel In625 / Stellite / MCrAlY / Ti-6Al-4V Ti64 / Stainless Steel 316L or Agglomerated Sintered Fine WC-10Co-4Cr / Chrome Carbide Cr3C2-NiCr / Molybdenum Powder for HVAF / HVOF / Flame / Plasma ID or Flash Carbide Thermal / Cold Spraying and Laser Cladding or PTA Clad Pipe / Weld Overlay Tube Elbow, Spherical Cast / Fused Tungsten Carbide Powder / Titanium Carbide Cemented TiC Sintered Hardmetal Wear Tile or Ring / Flexible Brazing Rope etc.