FerroTiC Titanium Carbide Hardface Powder for Brake Disc HVOF Spraying or Laser / PTA Plasma Overlay Cladding or Cored Wire Filler of Wear, Corrosion, Cavitation Resist

11

11

1. AMTmetalTech Unique Top Quality World Low Price FerroTiC Titanium Carbide Hardface Powders for Brake Disc HVOF Spraying or Conical Mining Bit Laser / PTA Plasma Overlay Cladding or Cored Wire Filler Specifications

Type | TiC | Cr+ Ni | C+Si+Mo+Nb | N+Mn+Co | Fe | Density | Hardness | Corrosion Resist | Temperature Resist | Powder Size | Application | Character |

T70 | 69-71 | 7-14 | 0.01-3.0 | 0.01-9.0 | Balance | ≈5.7 g/Cm3 | HRA88-89 | Better than 316L | up to 800℃ | 15-53um, 53-150um | HVOF, Cored Wire | Volume Price is 1/4 of WC-10Co-4Cr |

T33E | 32-34 | 25-31 | 0.5-4.0 | 0.1-6.0 | Balance | ≈6.8 g/Cm3 | HRC40-50 | Better than 316L | up to 700℃ | Laser, PTA Cladding | Volume Price is 1/2 of Stellite | |

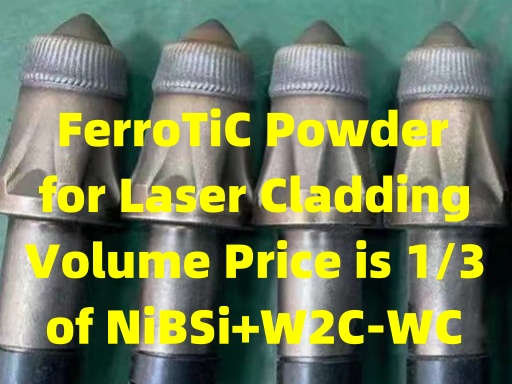

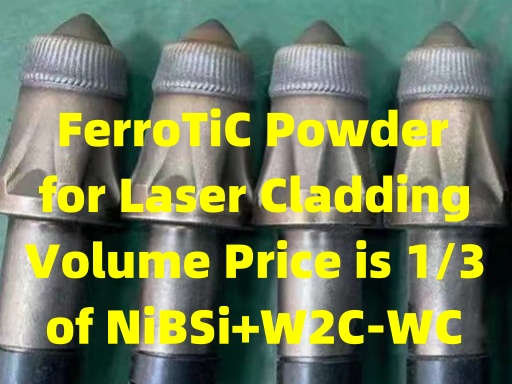

T33W | 32-34 | 15-21 | 0.5-3.0 | 0.1-6.0 | Balance | ≈6.8 g/Cm3 | HRC51-55 | Better than 17-4PH | up to 550℃ | Volume Price is 1/3 of 40%NiBSi + W2C-WC, T25W no need preheat. | ||

T25W | 24-26 | 15-21 | 0.5-2.0 | 0.1-5.0 | Balance | ≈7.1 g/Cm3 | HRC36-44 | |||||

T25C | 24-26 | 15-35 | 1.0-3.0 | 0.1-6.0 | Balance | ≈7.1 g/Cm3 | HRC36-44 | Better than 316L | up to 550℃ | Super Cavitation & very good Wear Resist |

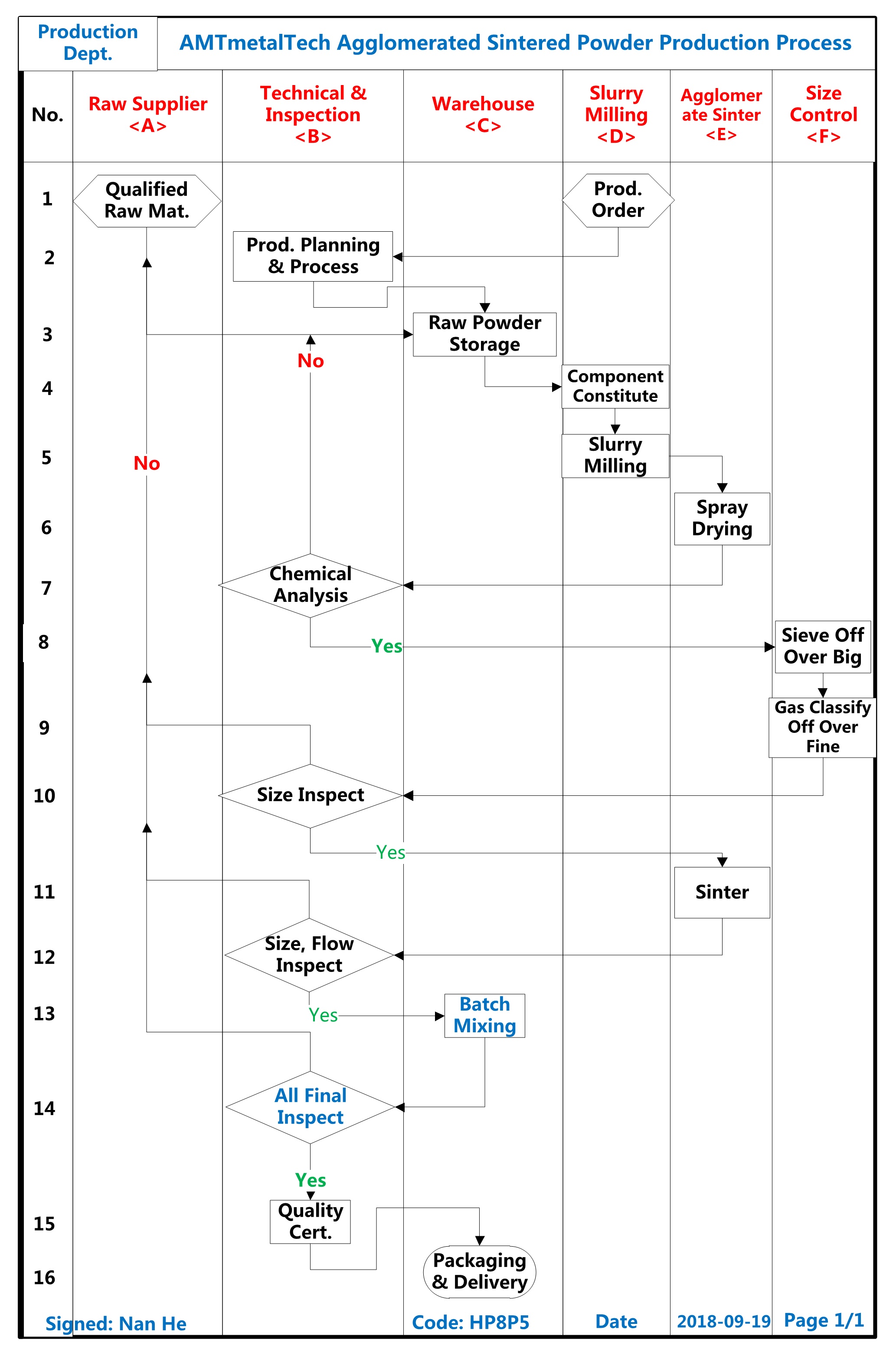

2. AMTmetalTech Unique Top Quality World Low Price FerroTiC Titanium Carbide Hardmetal Powders for Brake Disc HVOF Spraying or Conical Mining Bit Laser / PTA Plasma Overlay Cladding or Cored Wire Filler Production

T25W is very suitable for Euro7 Brake Disc High Speed Laser Cladding Hardface. T25W coating is no cracking without preheating.

AMTmetalTech unique FerroTiC Powder is the pure TiC clad with Stainless Steel to avoid the headache of pure TiC oxidizing and not easy to be wet bonded with steel during weld overlaying or thermal spraying.

The Tungsten Carbide volume rate in WC-10Co-4Cr is about 77%. The Titanium Carbide volume rate in T70=70%TiC+30%Stainless Steel is about 79%. The wear resistance of T70 is very good and close to WC-10Co-4Cr. The volume price of T70 is very competitive only 1/4 one quarter of the WC-10Co-4Cr for HVOF, HVAF or Plasma Spraying Brake Discs, Valves, Pistons, Drill Rods or Cored Wire Filler etc.

The Tungsten Carbide volume rate in 60%W2C-WC+40%NiBSi is about 43%. The Titanium Carbide volume rate in T33W=33%TiC+67%Stainless Steel is about 44%. The wear resistance of T33W is very good and close to 60%W2C-WC+40%NiBSi. The volume price of T33W is very competitive only 1/3 one third of the 60%W2C-WC+40%NiBSi for Laser or PTA Plasma cladding Brake Discs, Conical Mining Drill Bits etc.

T33E=33%TiC+67%Elevated Temperature Erosion Resist Austenite Stainless Steel is very good for Gas Valve Laser or PTA Plasma Cladding in Car Industry.

T25C=25%TiC+75% Duplex Stainless Steel can be very good Cavitation resist in addition to good corrosion resist and very good abrasion resist no cracking tendancy without preheating for Laser or PTA Plasma Cladding Hydro Turbine Runners, Propeller Blades, Impeller Runners, Pumps etc. The Titanium Carbide volume rate in T25C is about 35%.

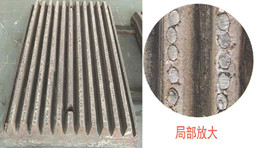

T33W Laser Clad Mud Pump Liner T33E Gas Valve Cladding T25C Powder for Cavitation Resist

3. AMTmetalTech Unique Top Quality World Low Price FerroTiC Titanium Carbide Hardface Powders for Brake Disc HVOF Spraying or Conical Mining Bit Laser / PTA Plasma Overlay Cladding or Cored Wire Filler Advantages

FerroTiC Advantages | FerroTiC, T70=70%TiC+SS | Pure TiC |

Density | about 6.1 | 4.93 |

TiC Grain Size | 1-2um | 20-53um, 53-150um |

Coating Homogeneity | Homogenious for T70 is dissolved to be fine TiC | Less Homogenious for Thick TiC easy to float |

Coating Brittleness | Less Brittle for fine 70%TiC already bonded with SS | More Brittle for pure thick TiC |

Bonding after Cladding | Better bonding for fine TiC already bonded with SS during vacuum sintering before cladding | Pure thick TiC is easy to be oxidized and less easy to be bonded with SS during cladding |

Cracking Tendency of Coating | Less Cracking Tendency | More Cracking Tendency |

TiC content rate allowed in coating to prevent cracking | Higher | Less |

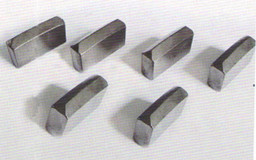

4. AMTmetalTech Unique Top Quality World Low Price FerroTiC Titanium Carbide Steel Cemented Hardmetal Wear Parts

The wear resistance of AMTmetalTech Unique Titanium Carbide Hardmetal is as Ferro-Titanit & close to Tungsten Carbide Hardmetal. The volume price is much lower than Tungsten carbide Hardmetal for the Low density.

Type | TiC, wt% | Density, g/Cm3, min. | Typical Hardness, HRA | Bend Strength, MPa, min. | Porosity | Impact, J/Cm3, min. | Description | Properties | Applications |

MT-316LTiC50 | 50 | 6.0 | 86 | 1800 | 316L Titanium Carbide Hardmetal with 316L matrix | 1、High hardness and good corrosion resist. | Mainly for Wear Parts and Crusher inserts.

| ||

MT-316LTiC60 | 60 | 5.7 | 88 | 1500 | |||||

MT17-4TiC50 | 50 | 6.0 | HRC50 Sintered, HRC68 Quenched | 2300 | 17-4 Titanium Carbide Hardmetal with 17-4 matrix | ||||

MT-HMTiC50 | 50 | 6.0 | 85.0 | 2800 | A04B00 | 13 | Titanium Carbide HardmetaL with High Manganese Steel matrix similar as Ferro-Titanit. | 1、High hardness and Good toughness. | Mainly for Mining Inserts and Bits.

|

MT-HMTiC54 | 54 | 5.9 | 86.0 | 2600 | A04B00 | 12 | |||

MT-HMTiC56 | 56 | 5.8 | 87.0 | 2400 | A04B00 | 12 | |||

MT-HMTiC59 | 59 | 5.7 | 88.0 | 2200 | A04B00 | 10 | |||

MT-HMTiC63 | 63 | 5.6 | 88.5 | 1800 | A04B00 | 10 | |||

MT-HMTiC67 | 67 | 5.5 | 89.0 | 1800 | A04B02 | 10 | |||

MT-HMTiC72 | 72 | 5.4 | 90.0 | 1800 | A04B02 | 9 | |||

MT-STTiC35 | 35 | 6.5 | HRC57 Sintered, Annealed, Quenched | 2200 | A04B00 | 5.9 | Titanium Carbide HardmetaL with tool steel matrix similar as Ferro-Titanit. | 1、High hardness and Good toughness. | Mainly for Cutters and Moulds.

|

Please send us email to export@AMTmetalTech.com about FerroTiC Titanium Carbide for HS-LMD Laser Deposit Euro7 Brake Disc or Conical Mining Bit Hardface, LaNi5 AB5 / TiMn2 AB2 / TiFe AB Hydrogen Storage Alloy, HDH Hydride-dehydride Titanium Ti64 Powder Sintered Billet Forge Superior than HIP Hot Isostatic Pressing, Gas Atomized Powder Bed Fusion / PM / MIM / SLS / SLM / Binder Jetting Ceramic 3D Printed Copper / Cobalt / Vehicle or Automobile Car Gear, Raney Nickel Aluminum NiAlMo Mesh Cathode Catalyst of Electrolysis Hydrogeneration Fibre Felt / Hastelloy / Inconel In625 / Stellite / MCrAlY / CoNiCrAlY / NiCoCrAlY / Ti 6Al 4V / Duplex Stainless Steel & 316L or Agglomerated Sintered WC-10Co-4Cr / WC-12Co / Cr3C2-NiCr / Moly Powder for HVAF / HVOF Thermal or Cold Spraying or PTA Clad Weld Overlay Elbow, Cast or Fused Tungsten Carbide Brazing Rope, Hafnium Zirconium Wires / Rods for Plasma Cutting from Crystal Iodide Hafnium Bar, Tantalum Ta & Niobium Nb for Alloy Melting or Foil / Target / Sheet Welding, Molybdenum Lanthana MoLa Filament EDM Wire, Amorphous Fine Powder Tube Inside ID Spraying replacing Chrome Plating for severe Erosion Cavitation high temperature abrasion resist of Stirrer Blade / Hydro Turbine Runner / Electronics; Hardmetal Cemented Clad Mud Pump Liner / Pipe / Tile / Super Wear Plate; PDC Diffusion Bonding, Diamond Bearing etc.