AMTmetalTech Quality Self-fluxing Nickel Alloy Powders for Flame Spraying+Fuse and PTA Plasma or Laser Cladding of Erosion and Abrasion Resist

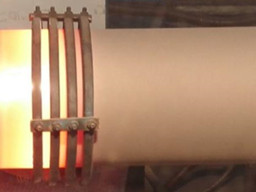

1.AMTmetalTech Quality Self-fluxing Nickel Powders for Flame Spraying+Fuse and PTA Plasma or Laser Cladding of Erosion, Abrasion Resist Character and Application

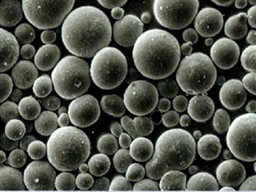

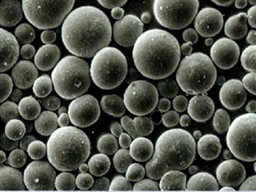

AMTmetalTech Quality Erosion and Abrasion Resist Self-fluxing Nickel alloy powders have good sphericity, flow ability, which common sizes are 15-45um,20-53um, 45-125um for Flame Spraying+Fuse / HVOF / HVAF / Plasma thermal spraying or Laser / PTA Plasma cladding various parts etc.

2.AMTmetalTech Quality Self-fluxing Nickel Alloy Powders for Flame Spraying+Fuse and PTA Plasma or Laser Cladding of Erosion and Abrasion Resist Packaging

The standard packaging is by plastic bottle per 5 kg. We can do according tothe customer requirements for packaging.

3.AMTmetalTech Self-fluxing Nickel Powders for Flame Spraying+Fuse and PTA Plasma or Laser Cladding of Erosion and Abrasion Resist Main Specifications as in the below table

Name | Powder Type | Hardness | Reference | Process | Properties/Applications | ||

Metco | Praxair | Hoganas | |||||

AMNiCrBSi60 | Ni-17Cr-4Fe-4Si-3.5B-C | HRC 60+ | 15E, 15F | Ni- 167 | 1560-00, 1060-00, 1360-20 | Self-F, HVOF, HVAF | ● Very Good Wear Resist |

AMNiCrBSi50 | Ni-11Cr-3Fe-4Si-2.5B-C | HRC 50+ | 1550-00, 1050-00, 1350-00 | Self-F, HVOF, HVAF | ● Good Wear and Erosion Resist | ||

AMNiCrBSi45 | Ni-10Cr-3Fe-3.5Si-2.5B-C | HRC 45+ | Metco 14E | 1045-00, 1245-00, 1345-00 | Self-F, Laser, AP, PTA | ● Good Wear, Corrosion, Heat and Crack Resist | |

AMNiCrBSi40 | Ni-10Cr-3Fe-3.5Si-1.5B-C | HRC 40+ | 1540-00, 1040-00, 1340-00 | Self-F, Laser, AP, PTA | ● Medium hard. Good matrix of tungsten carbide | ||

AMNiCrBSi35 | Ni-10Cr-3Fe-3Si-1.5B-C | HRC 35+ | Metco 12C | 1035-40, 1135-40 | Self-F, Laser, AP, PTA | ● Suitable for Light Impact Parts and Glass Mold | |

AMNiCrBSi60WC10Ni35 | 35%WC/1 0Ni-65%AMNiCrBSi60 | Blend | Metco 36C | Self-F, HVOF, HVAF, AP | ● Very Good Corrosion Resist and Good Wear | ||

AMNiCrBSi60WC12Co80 | 80%WC/1 2Co-20%AMNiCrBSi60 | Blend | Metco 32C | Self-F, HVOF, HVAF, AP | ● Very Good Wear Resist and Good Erosion | ||

AMNiBSi40 | Ni-3.5Si-3.5B-C | HRC 40+ | Amdry 7050 | Ni- 298 | 1559-40 | Self-F, Laser, AP, PTA | ● Medium hard. Good matrix of tungsten carbide |

AMNiBSi35 | Ni-3Si-2B | HRC 35+ | Metco 7010 | Ni- 489 | 1538-40 | Self-F, Laser, AP, PTA | ● Good for buffer layer, build up or carbide matrix |

AMNiBSi25 | Ni-3Si-1.5B | HRC 25+ | 1025-40 | Self-F, Laser, AP, PTA | ● Suitable for Glass Mold and Impact Parts | ||

AMNiBSi20 | Ni-2.5Si-1.5B | HRC 20+ | 1520-00, 1020-00, 1623-05 | Self-F, Laser, AP, PTA | ● Good for surfacing cast iron and glass molds | ||

AMTmetalTech is no way affiliated with the original equipment manufacturers (OEM) mentioned. All trademark listed herein are not of OEM's origin. References to the OEM's part numbers are for your convenience only.

Please send us email about Atomized Self-fluxing Nickel Alloy NiBSi / Hastelloy / Inconel / Stellite / MCrAlY / NiCrCoAlY / Iron Alloy 316L or Agglomerated Sintered Fine WC / Chrome Carbide Nickel Chrome Cr3C2 / Molybdenum Powder and Wire for HVAF / HVOF / Flame / Plasma ID or Flash Carbide thermal spraying and Laser or PTA Cladding, Spherical Cast / Fused / Monocrystalline / Macrocrystalline Tungsten Carbide Powder or Sintered Tungsten Carbide Cemented Hardmetal Pellets Flexible Welding Rope for Hardfacing overlaying etc.