Metal Injection Molding MIM / Auto Parts PM / Soft Magnet Steel

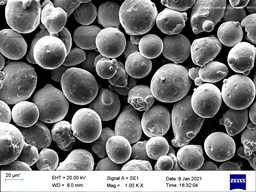

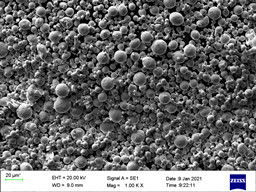

Gas or Water Atomized Super Fine Alloy Powders

Gas Atomized Fine Powder Water Atomized Powder Soft Magnet Parts Metal Injection Molding Part

1. AMTmetalTech Quality Metal Injection Molding MIM/PM or FeSi Soft Magnet Steel Gas or Water Atomized Super Fine Alloy Powders main type and chemical

AMTmetalTech produces Metal Injection Molding MIM/PM or FeSi Soft Magnet Super Fine Alloy Powders Gas Shielded High Pressure Water Atomized or Non-vacuum Nitrogen Gas Atomized in thousands tons annually at very competitive quality and pricing including FeSiBCr Amophous powder etc.

型号Type | 化学成分Chemical Composition, wt% | ||||||||||||

C | Cr | Ni | Mo | Si | Mn | S | P | V | W | Nb | Cu | Fe | |

MT-316L | ≤0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | ≤1.00 | ≤2.00 | ≤0.03 | ≤0.045 | Balance | ||||

MT-17-4PH | ≤0.07 | 15.5-17.5 | 3.0-5.0 | ≤1.00 | ≤1.00 | ≤0.03 | ≤0.04 | 0.15-0.45 | 3.0-5.0 | Balance | |||

MT-420 Steel | 0.16-0.25 | 12.0-14.0 | ≤0.75 | ≤1.00 | ≤1.00 | ≤0.04 | ≤0.03 | Balance | |||||

MT-M2 High Speed Steel | 0.80-0.90 | 3.80-4.40 | ≤0.30 | 4.50-5.50 | 0.20-0.45 | 0.15-0.40 | ≤0.03 | ≤0.03 | 1.75-2.20 | 5.50-6.75 | ≤0.25 | Balance | |

MT-H13 High Speed Steel | 0.32-0.45 | 4.75-5.50 | 1.1-1.5 | 0.8-1.2 | 0.2-0.5 | ≤0.03 | ≤0.03 | 0.8-1.2 | Balance | ||||

MT4140 Steel | 0.30-0.50 | 0.80-1.20 | 0.20-0.30 | ≤0.60 | ≤1.00 | ≤0.03 | ≤0.03 | Balance | |||||

MT4340 Steel | 0.38-0.43 | 0.7-0.9 | 1.65-2.00 | 0.2-0.3 | 0.15-0.35 | 0.6-0.8 | ≤0.03 | ≤0.03 | Balance | ||||

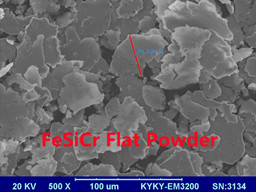

AM-FeSiCr | ≤0.02 | 4.0-6.0 | 3.0-7.0 | ≤0.05 | ≤0.03 | ≤0.03 | Balance | ||||||

AM-FeSiAl | ≤0.02 | ≤0.02 | 9.0-10.0 | ≤0.03 | ≤0.03 | Al 5.0-6.0 | Balance | ||||||

AM-FeNi50 | ≤0.01 | 49.0-51.0 | ≤0.20 | ≤0.01 | ≤0.15 | ≤0.03 | ≤0.03 | Balance | |||||

AM-FeSi6.5 | ≤0.02 | ≤1.0 | 6.3-6.7 | ≤0.15 | ≤0.03 | ≤0.03 | Balance | ||||||

AM-FeSi3.5 | ≤0.02 | ≤1.0 | 3.3-3.7 | ≤0.15 | ≤0.03 | ≤0.03 | Balance | ||||||

2. AMTmetalTech Metal Injection Molding MIM/PM or FeSi Soft Magnet Steel Gas Atomized Super Fine Alloy Powders Particle Size Distribution and Oxygen content:

Particle Size Distribution PSD | D10 | D50 | D90 | Oxygen |

Non-vacuum Nitrogen Gas Atomizing | 4-6um | 8-13um | 18-23um | ≤1500PPM |

Non-vacuum Nitrogen Gas Atomizing | 26-29um | 34-39um | 46-51um | ≤1500PPM |

High Pressure Water Atomizing Gas Shield | 2-4um | 5-9um | 15-20um | ≤4000PPM |

Typical PSD of Water Atomized Stainless Steel Powders for PM is -100+325 Mesh.

Other type and chemical, Particle Size Distribution is available as inquired.

3. AMTmetalTech Quality Metal Injection Molding MIM/PM or FeSi Soft Magnet Steel Gas Atomized Super Fine Alloy Powders Packaging

The standard packaging is 25kg per Iron Drum. We can do according to the customer requirements for packaging.

Please send us email about Atomized Additive Manufacturing Powder Bed Fusion / Binder Jet 3D Printing Cobalt / Metal Injection Molding MIM / Nano Metal & Oxide Powder, Nickel Aluminum Alloy NiAlMo / Inconel In625 / Stellite / MCrAlY / CoNiCrAlY / NiCoCrAlY / Ti-6Al-4V Ti64 / Stainless Steel 316L or Agglomerated Sintered WC-10Co-4Cr / WC-12Co / Chrome Carbide Cr3C2-NiCr / Molybdenum Powder for HVAF / HVOF / Plasma ID Thermal / Cold Spraying and Laser Cladding or PTA Clad Pipe / Weld Overlay Tube Elbow Rotator Positioner, Ferro TiC Titanium Carbide Cemented Sintered Hardmetal / Tungsten Carbide Brazing Rope etc.