High Speed Laser Deposit HS-LMD Clad Brake Discs per Euro7 by Titanium Carbide Powder Volume Price 1/3 of Tungsten Carbide

1. AMTmetalTech High Speed Laser Deposit HS-LMD Clad Brake Disc per Euro7 by Titanium Carbide Powder Volume Price 1/3 of Tungsten Carbide

Euro7 Vented Brake Discs Euro7 Heavy Brake Discs Euro7 Solid Brake Discs

The dust emission from braking system has to be max. 7mg/100km as per Euro7 car emission standard. AMTmetalTech is providing Top Quality World Low Price Super Wear & Corrosion Resist Titanium Carbide Alloy Deposit Coated Brake Discs as per Euro7 standard by High Speed Powder Laser Metal Deposition HS-LMD.

2. AMTmetalTech Top Quality World Low Price Titanium Carbide Alloy FerroTiC Laser Cladding Powder Volume Price 1/3 of Tungsten Carbide for Euro7 Brake Disc

AMTmetalTech T33W powder can replace NiBSi+60%W2C-WC powder very well! T33W powder Volume Price is only 1/3 of NiBSi+60%W2C-WC! T33W powder is very suitable for High Speed Powder Laser Metal Deposition HS-LMD Cladding, which have Very Good Wear Resistance, Lower Density 6.9g/cm3 with 33% TiC.

Type | TiC | Cr+ Ni | C+Mo+Nb | N+Mn+Co | Fe | Density | Hardness | Corrosion Resist | Temperature Resist | Powder Size | Application | Character |

T33W | 32-34 | 15-17 | 1.0-3.0 | 4.0-6.0 | Balance | ≈6.8 g/Cm3 | HRC51-55 | Better than 17-4PH | up to 550℃ | 15-53um | High Speed Laser Cladding | Volume Price is 1/3 of 40%NiBSi + W2C-WC, T25W no need preheat. |

T25W | 24-26 | 15-20 | 0.5-2.0 | 3.0-5.0 | Balance | ≈7.1 g/Cm3 | HRC44-49 |

AMTmetalTech FerroTiC is well bonded during Blend Powder Laser Depositing because FerroTiC is already bonded by Vacuum Sintering 1-2um TiC with Stainless Steel before Laser Deposit. If Pure TiC powders are simply blended with Stainless Steel Powders, Pure TiC will not be well wetted during Blend Powder Laser Depositing.

Compared with Pure TiC powders, AMTmetalTech FerroTiC powder T33W has Better Bonding, Better Homogeneity in Coating, Less Brittle, Less Cracking Tendency!

T33W or T25W are all very suitable for Euro7 Brake Disc HS-LMD Laser Cladding. T33W is higher wear resistance & need preheating than T25W.

3. AMTmetalTech Top Quality World Low Price High Speed Laser HS-LMD Deposit Brake Discs per Euro7 Cladding Service by Titanium Carbide Alloy Powder Volume Price 1/3 of Tungsten Carbide

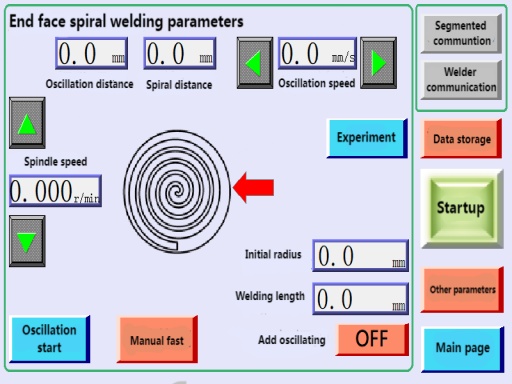

HS-LMD Deposit Cladding Brake Disc Cladding Control FerroTiC Cladding Powder

Please send us email to export@AMTmetalTech.com about FerroTiC Titanium Carbide for HS-LMD Laser Deposit Euro7 Brake Disc or Conical Mining Bit Hardface, LaNi5 AB5 / TiMn2 AB2 / TiFe AB Hydrogen Storage Alloy, HDH Hydride-dehydride Titanium Ti64 Powder Sintered Billet Forge Superior than HIP Hot Isostatic Pressing, Gas Atomized Powder Bed Fusion / PM / MIM / SLS / SLM / Binder Jetting Ceramic 3D Printed Copper / Cobalt / Vehicle or Automobile Car Gear, Raney Nickel Aluminum NiAlMo Mesh Cathode Catalyst of Electrolysis Hydrogeneration Fibre Felt / Hastelloy / Inconel In625 / Stellite / MCrAlY / CoNiCrAlY / NiCoCrAlY / Ti 6Al 4V / Duplex Stainless Steel & 316L or Agglomerated Sintered WC-10Co-4Cr / WC-12Co / Cr3C2-NiCr / Moly Powder for HVAF / HVOF Thermal or Cold Spraying or PTA Clad Weld Overlay Elbow, Cast or Fused Tungsten Carbide Brazing Rope, Hafnium Zirconium Wires / Rods for Plasma Cutting from Crystal Iodide Hafnium Bar, Tantalum Ta & Niobium Nb for Alloy Melting or Foil / Target / Sheet Welding, Molybdenum Lanthana MoLa Filament EDM Wire, Amorphous Fine Powder Tube Inside ID Spraying replacing Chrome Plating for severe Erosion Cavitation high temperature abrasion resist of Stirrer Blade / Hydro Turbine Runner / Electronics; Hardmetal Cemented Clad Mud Pump Liner / Pipe / Tile / Super Wear Plate; PDC Diffusion Bonding, Diamond Bearing etc.