Top Quality World Low Price Cast or Fused Tungsten Carbide

Powder Brazing Flexible Ropes

1. AMTmetalTech Top Quality World Low Price Cast or Fused Tungsten Carbide Powder Brazing Flexible Ropes Description

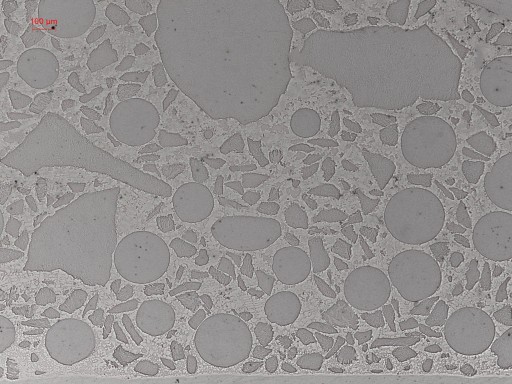

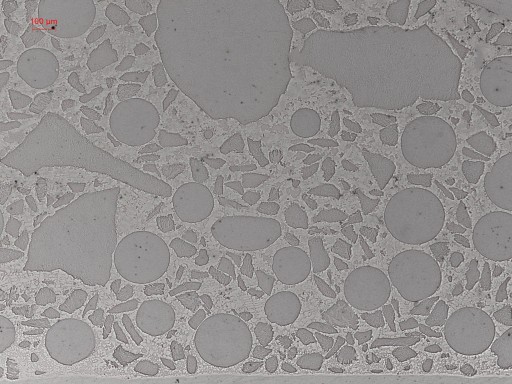

AMTmetalTech Top Quality World Low Price Tungsten Carbide Brazing Flexible Ropes are made with Crushed Cast or Fused Tungsten Carbide Powder, Spherical Cast or Fused Tungsten Carbide Powder and Self-fluxing Nickel Alloy Powder mixture around the nickel center wire. Typical Diameters are 4.0, 5.0, 6.0, 8.0mm. The Self-fluxing Nickel Alloy powder content is about 35%. The weld overlay is very High Abrasion and Erosion resist.

2. AMTmetalTech Top Quality World Low Price Cast or Fused Tungsten Carbide Powder Size and Properties for Brazing Flexible Ropes

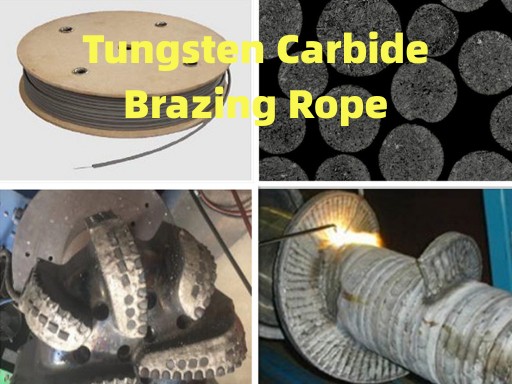

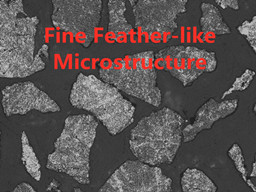

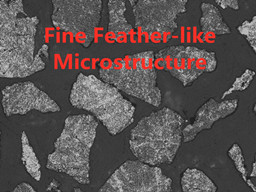

AMTmetalTech Top Quality World Low Price AMR25 contains 75% Crushed Cast or Fused Tungsten Carbide Powder + 25% Spherical Cast or Fused Tungsten Carbide Powder as above microstructure, which combined performance is very good, are all made from virgin raw materials. The high feather-like microstructure rate in Cast or Fused Tungsten Carbide powder is the super abrasion resist performance guarantee. The stable Top Quality of raw material powder is the quality consistence guarantee of our Tungsten Carbide Hardfacing Flexible Brazing Ropes.

Type | Tungsten Carbide Type 65% WC-W2C + 35% NiSiB or NiCrBSi | Tungsten Carbide Hardness | Character, Carbon C 3.8-4.0% | WC-W2C Powder Size |

AMR25 | Cast Tungsten Carbide or Fused Tungsten Carbide Powder 25% SFTC + 75% FTC | 25% HV2100-2400 + 75% HV2700-3100 | High Hardness and Very Good Abrasion Resist, Economic | 0.1-0.6mm for Rope D4mm, 0.1-0.7mm for Rope D5/6mm, 0.1-0.8mm for Rope D8mm |

AMRSFTC | Spherical Fused Tungsten Carbide SFTC or Spherical Cast Tungsten Carbide SCTC | HV2700-3100 | Very High Hardness and Very Good Abrasion Resist, Expensive | 0.1-0.4mm for all Rope D4, 5, 6, 8mm |

AMRFTC | Crushed Cast Tungsten Carbide CTC or Fused Tungsten Carbide FTC Powder | HV2100-2400 | High Hardness and Good Abrasion Resist, Economic | 0.1-0.6mm for Rope D4mm, 0.1-0.7mm for Rope D5/6mm, 0.1-0.8mm for Rope D8mm |

3. AMTmetalTech Top Quality World Low Price Cast or Fused Tungsten Carbide Powder Flexible Brazing Ropes Applications

AMTmetalTech Top Quality Cast or Fused Tungsten Carbide Powder Flexible Brazing Ropes are widely used for Severe Abrasion and Erosion Resist in Mining, Oil and Gas Drilling, Agriculture, Construction, Chemical and Food Industries etc.

15kg Tungsten Carbide Rope 5kg Tungsten Carbide Rope Agriculture Abrasion Tools

4. AMTmetalTech Top Quality World Lowest Price Cast or Fused Tungsten Carbide Powder Flexible Brazing Ropes Packaging

The standard packaging is by wooden spool per 15kg or Plastic Spool per 5kg. We can do the other packaging according to the customer requirements.

Please send us email to export@AMTmetalTech.com about HDH Hydride-dehydride Titanium Ti64 Powder Sintered Forge Superior than HIP Hot Isostatic Pressing, Gas or Water Atomized Additive Manufacturing Powder Bed Fusion / MIM / Binder Jet 3D Printing Cobalt / Vehicle or Car Part, Nickel Aluminum Alloy NiAlMo Catalyst / Inconel In625 / Stellite / MCrAlY / CoNiCrAlY / NiCoCrAlY / Ti 6Al 4V / Duplex Stainless Steel & 316L or Agglomerated Sintered WC-10Co-4Cr / WC-12Co / Cr3C2-NiCr / Molybdenum Spherical Powder for HVAF / HVOF Thermal or Cold Spraying and Speed Laser Cladding or PTA Clad Weld Overlay Elbow, FerroTiC for Brake Disc, Tungsten Carbide Brazing Rope, Hafnium Wires / Rods for Plasma Cutting from Crystal Iodide Hafnium Bar, Tantalum Ta & Niobium Nb for Alloy Melting, Amorphous Fine Powder Tube Inside ID Spraying replacing Chrome Plating for severe Erosion Cavitation high temperature abrasion resist of Cylinders / Pistons / Roller / Screw Rotors / Valve / Stirrer Blade / Hydro Turbine Runner; Hardmetal Cemented Clad Mud Pump Liner / Pipe / Sleeve / Glass Mold / Tile / Super Wear Plate; PDC Diffusion Bonding, Diamond Bearing etc.