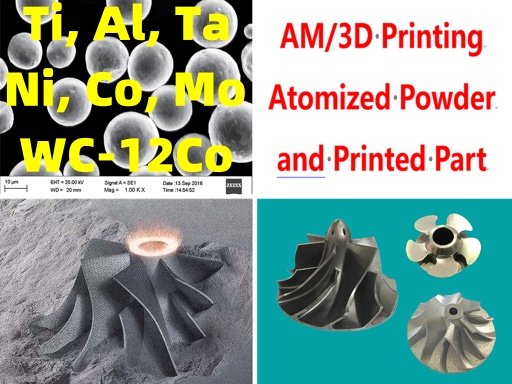

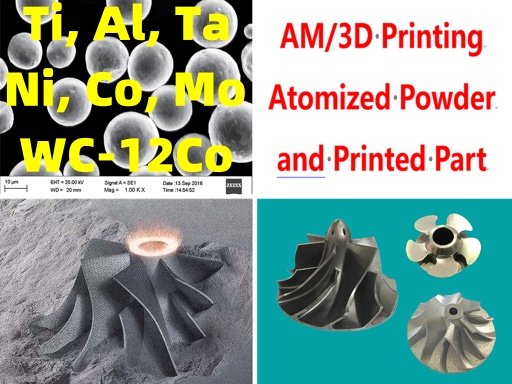

Top Quality World Lowest Price Vacuum Gas Atomized Alloy Powders for Binder Jet

/ Bed Fusion Metal Additive Manufacturing AM or 3D Printing & Printed Parts

1. AMTmetalTech Top Quality World Lowest Price Vacuum Gas Atomized Alloy Powders for Binder Jet / Bed Fusion Metal Additive Manufacturing AM or 3D Printing main type and chemical

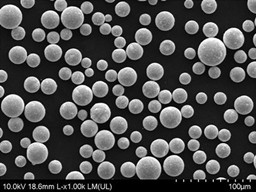

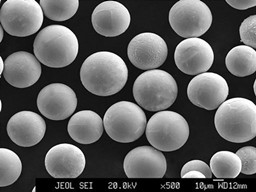

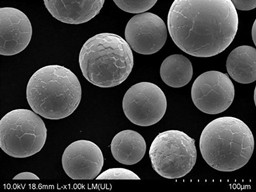

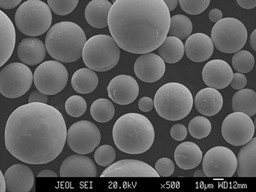

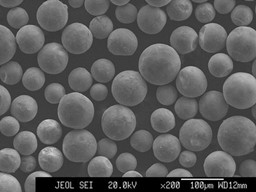

AMTmetalTech produces Metal Additive Manufacturing AM or 3D Printing Vacuum Gas Atomized Alloy Powders in hundreds tons annually at very competitive quality and pricing widely for Binder Jetting Technology, Laser Powder Bed Fusion, Directed Energy Deposition, Cold Spraying etc.

2. AMTmetalTech Top Quality World Lowest Price Vacuum Gas Atomized Alloy Powders for Binder Jet / Bed Fusion Metal Additive Manufacturing AM or 3D Printing Particle Size Distribution & Oxygen content

Typical Size: 26-51um, 4-22um for Binder Jetting Technology. 26-51um, 53-105um for Cold Spraying. 15-45um, 15-53um for Laser Powder Bed Fusion. 53-105um for Directed Energy Deposition etc. Oxygen Content: Normally ≤500PPM for Ni, Fe, Co, Cu alloys; ≤1500PPM for Titanium, Al, Mg alloys.

Powder Sphericity: ≥0.9

Other type and chemical, Particle Size Distribution is available as inquired.

3. AMTmetalTech Top Quality World Lowest Price Vacuum Gas Atomized Alloy Powders for Binder Jet / Bed Fusion Metal Additive Manufacturing AM or 3D Printing Packaging

The standard packaging is 5kg per Vacuum Bag or Plastic Bottle. We can do according to the customer requirements for packaging.

Type | Chemical Composition, wt% | ||||||||||||||

C | Cr | Ni | Mo | Si | Mn | S | P | Nb | Cu | V | Ti | Fe | Co | Al | |

Ti-6Al-4V, Ti64 | 3.50-4.50 | Balance | ≤0.3 | 5.5-6.75 | |||||||||||

AlSi10Mg | ≤0.05 | 9.0-11.0 | ≤0.45 | Sn≤0.01 | Pb≤0.01 | Zn≤0.1 | ≤0.1 | ≤0.15 | ≤0.55 | Mg0.2-0.45 | Balance | ||||

Inconel 625 | ≤0.1 | 20.0-23.0 | Balance | 8.0-10.0 | ≤0.5 | ≤0.5 | ≤0.015 | ≤0.015 | 3.15-4.15 | ≤0.4 | ≤5.0 | ≤1.0 | ≤0.4 | ||

Inconel 718 | ≤0.08 | 17.0-21.0 | 50.0-55.0 | 2.8-3.3 | ≤0.35 | ≤0.35 | ≤0.01 | ≤0.01 | 4.75-5.50 | ≤0.30 | B≤0.006 | 0.65-1.15 | Balance | ≤1.0 | 0.2-0.8 |

Hastelloy X | 0.05-0.15 | 20.5-23.0 | Balance | 8.0-10.0 | ≤1.00 | ≤1.00 | ≤0.015 | ≤0.025 | W0.20-1.00 | ≤0.50 | B≤0.01 | ≤0.15 | 17.0-20.0 | 0.50-2.50 | ≤0.50 |

316L Stainless Steel | ≤0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | ≤1.00 | ≤2.00 | ≤0.03 | ≤0.045 | Balance | ||||||

17-4PH | ≤0.07 | 15.5-17.5 | 3.0-5.0 | ≤1.00 | ≤1.00 | ≤0.03 | ≤0.04 | 0.15-0.45 | 3.0-5.0 | Balance | |||||

MS1 Tool Steel | ≤0.03 | ≤0.5 | 17.0-19.0 | 4.5-5.2 | ≤0.1 | ≤0.1 | ≤0.01 | ≤0.01 | ≤0.50 | 0.6-0.8 | Balance | 8.5-9.5 | 0.05-0.15 | ||

Duplex Stainless Steel | ≤0.03 | 26.0-28.0 | 5.0-8.0 | 4.0-5.0 | ≤0.5 | ≤1.5 | ≤0.02 | ≤0.01 | Balance | N0.35-0.45 | |||||

CoCrMo | <0.35 | 27.0-30.0 | <0.5 | 5.0-7.0 | <1.0 | <1.0 | W<0.25 | B<0.01 | N<0.25 | <0.2 | <0.1 | <0.75 | Balance | <0.1 | |

CuCrZr | 0.5-1.5 | Zr .05-.25 | Balance | ||||||||||||

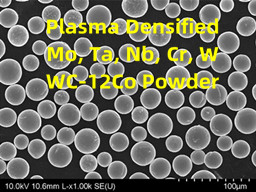

4. AMTmetalTech Top Quality World Lowest Price Plasma Densified High Melting Alloy Powders for Metal Additive Manufacturing or 3D Printing

Spherical Mo Metal Powder Spherical W Metal Powder Spherical Ta Metal Powder

AMTmetalTech produces high quality Plasma Densified High Melting Alloy Powders including Molybdenum, Tungsten, Tantalum, Niobium, Chromium, Tungsten Cemented Carbide Hardmetal Powders etc. for Metal Additive Manufacturing at very High Sphericity, High Purity, Low Oxygen, Good Flowability, Few Satellite Powder, No Porosity. Very good for Additive Manufacturing or 3D Printing etc.

Type | Purity | Oxygen | Sphericity | Sizes, um |

Mo, W, Ta, Nb, WC-12Co, Cr etc. | ≥99.95% | ≤0.03% | ≥98% | 5-25, 15-45, 15-53, 45-90, 45-105, 53-150 |

Spherical Nb Metal Powder Spherical Cr Metal Powder Spherical WC-12Co Powder

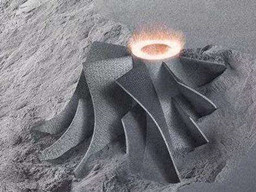

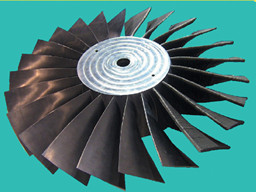

5. AMTmetalTech Top Quality World Lowest Price Metal Additive Manufacturing AM or 3D Printed Parts

AMTmetalTech Metal Additive Manufacturing AM or 3D Printing machines include EOS M400, EOS M290, BLT S310 for SLS and SLM; Arcam Q20 for Electron Beam Melting of Max. size 400 * 400 * 400 mm3 and Accuracy 20-100um. Please send drawings for inquiry various Printed Parts.

EOS M400 for SLS and SLM EOS M290 for SLS and SLM BLT S310 for SLS and SLM

SLS Printed Steel Parts SLM Printed Duplex Steel 2207 SLS Printed Hastelloy X

SLM Printed Inconel 718 Electron Beam Melting In625 Electron Beam Melting Ti64

Please send us email to export@AMTmetalTech.com about HDH Hydride-dehydride Titanium Ti64 Powder Sintered Forge Superior than HIP Hot Isostatic Pressing, Gas or Water Atomized Additive Manufacturing Powder Bed Fusion / MIM / Binder Jet 3D Printing Cobalt / Vehicle or Car Part, Nickel Aluminum Alloy NiAlMo Catalyst / Inconel In625 / Stellite / MCrAlY / CoNiCrAlY / NiCoCrAlY / Ti 6Al 4V / Duplex Stainless Steel & 316L or Agglomerated Sintered WC-10Co-4Cr / WC-12Co / Cr3C2-NiCr / Molybdenum Spherical Powder for HVAF / HVOF Thermal or Cold Spraying and Speed Laser Cladding or PTA Clad Weld Overlay Elbow, FerroTiC for Brake Disc, Tungsten Carbide Brazing Rope, Hafnium Wires / Rods for Plasma Cutting from Crystal Iodide Hafnium Bar, Tantalum Ta & Niobium Nb for Alloy Melting, Amorphous Fine Powder Tube Inside ID Spraying replacing Chrome Plating for severe Erosion Cavitation high temperature abrasion resist of Cylinders / Pistons / Roller / Screw Rotors / Valve / Stirrer Blade / Hydro Turbine Runner; Hardmetal Cemented Clad Mud Pump Liner / Pipe / Sleeve / Glass Mold / Tile / Super Wear Plate; PDC Diffusion Bonding, Diamond Bearing etc.