Top Quality World Low Price Polycrystalline Diamond Cutter or Tungsten Cemented Carbide Hardmetal Bearing and Long PDC by Diffusion Bonding

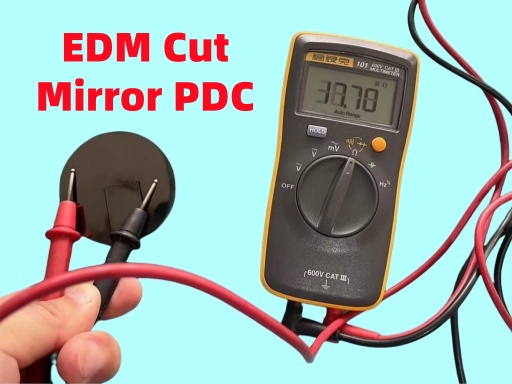

PDC Polycrystalline Diamond Cutter EDM Machinable Mirror PDC Polycrystalline Diamond Cutter

1. AMTmetalTech Top Quality World Low Price PDC Diamond or Tungsten Cemented Carbide Hardmetal Brazed Precision Bearings

1.1. AMTmetalTech Top Quality World Low Price Polycrystalline Diamond Cutter PDC Diamond or Tungsten Cemented Carbide Bearing Description

AMTmetalTech Top Quality World Low Price Polycrystalline Diamond Cutter PDC or Tungsten Cemented Carbide Bearing are made by precision brazing the PDC or Tungsten Cemented Carbide Hardmetal cutters on steel base and then make the precision machining to the whole workpiece containing the PDC cutters.

1.2. AMTmetalTech Top Quality World Low Price Polycrystalline Diamond Cutter PDC Diamond or Tungsten Cemented Carbide Bearing Advantages

AMTmetalTech strictly controls the temperature on the diamond during brazing to avoid the decomposition of the diamond.

AMTmetalTech’s high precision brazing makes the Polycrystalline Diamond Cutter PDC or Tungsten Cemented Carbide Hardmetal Button on the bearing has the precise location and all the Polycrystalline Diamond Cutter PDCs or Tungsten Cemented Carbide Buttons are on the same level.

AMTmetalTech Top Quality World Low Price Polycrystalline Diamond Cutter PDC or Tungsten Cemented Carbide Button has excellent abrasion resistance, impact resistance, superior hardness, good thermal conductivity and thermal stability. It is also suitable for highly corrosive environments and greatly improve the service life of the Bearing.

1.3. AMTmetalTech Top Quality World Low Price Polycrystalline Diamond Cutter PDC Diamond or Tungsten Cemented Hardmetal Bearing Applications

AMTmetalTech Top Quality World Low Price Polycrystalline Diamond Cutter PDC or Tungsten Cemented Carbide Hardmetal bearing can adapt to severe working environment and bear the grinding of drilling fluid, high load, high speed, strong impact force in drilling process. AMTmetalTech Top Quality World Low Price Polycrystalline Diamond Cutter PDC or Tungsten Cemented Carbide Bearings have high abrasion resistance, high corrosion resistance etc. and are very suitable for the oil field.

2. AMTmetalTech Top Quality World Low Price PDC Diamond Long Cutter by Diffusion Bonding

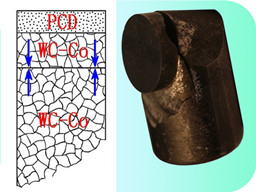

2.1. AMTmetalTech Top Quality World Low Price Polycrystalline Diamond Cutter PDC Diamond Long Cutter Description

AMTmetalTech Top Quality World Low Price long special-shaped Polycrystalline Diamond Cutter PDC cutter is connected by diffusion bonding betweent PDC and Hardmetal. The temperature of diffusion bonding is below 700℃. Through the long time of high pressure contact, the hardmetal joint has been formed by atomic diffusion. We can connect PDC Polycrystalline Diamond Cutter on drill bits, tool shanks and other hardmetal substrate.

2.2. AMTmetalTech Top Quality World Low Price Polycrystalline Diamond Cutter PDC Diamond Long Cutter Advantages

Low diffusion temperature under 700℃ has little harm to PCD diamond layer.

High precision Polycrystalline Diamond Cutter PDC to substrate can guarantee the dimensional tolerances.

The Polycrystalline Diamond Cutter PDC to substrate shear strength can be in excess of 400MPa.

High performance Polycrystalline Diamond Cutter PDC bit design has high penetration rate in mining.

The Joint Strength between Polycrystalline Diamond Cutter PDC and hardmetal is stronger than the hardmetal. The broken will be occurred in the hardmetal rather than at the joint.

The Polycrystalline Diamond Cutter PDC to substrate has no stress concentration, which prolongs bit’s lifetime.

2.3. AMTmetalTech Top Quality World Low Price Polycrystalline Diamond Cutter PDC Diamond Long Cutter Applications

AMTmetalTech Top Quality World Low Price Long Special-shaped PDC Polycrystalline Diamond Cutter is mainly used for high performance driller with high strength requirements which brazing is not satisfied. The Polycrystalline Diamond Cutter PDC bit made by diffusion bonding is widely used in oil mining for the excellent performance. Also we provide diffusion bonding service for customers.

Please send us email to export@AMTmetalTech.com about Nickel Amorphous HVAF or HVOF Tube Inside ID Spraying Fine Atomized Powder Better Corrosion risist than Hastelloy C276 / Inconel In625 / Stellite of severe Erosion, Cavitation, high temperature Abrasion resist; Duplex Stainless Steel Powder for Binder Jet Printing / Speed Laser / PTA cladding / Plasma weld overlaying Replacing Chrome Plating for Coated Cylinders / Pistons / Roller / Screw Rotors / Valve / Stirrer Blade / Hydro Turbine Runner; Tungsten Carbide Hardmetal Cemented Clad Mud Pump Liner / Pipe / Sleeve / Glass Mold and Super Wear Plate; PDC Diffusion Bonding, Diamond Bearing etc.