Unique Duplex Stainless Steel Powder D for Super Cavitation

& High Corrosion Resist Laser Cladding or PTA Plasma Weld Overlay

1. AMTmetalTech Unique Duplex Stainless Steel Powder D for Super Cavitation and Corrosion Resist Laser Cladding or PTA Plasma Weld Overlay Description

Cavitation resist need not only corrosion resist but also resist to blasting impact of fluid micro bubbles. Numerous practice has proved Duplex Stainless Steel is the best resist to cavitation. The microstructure from Duplex Stainless Steel coating under quick cooling of Laser Cladding or PTA Plasma Weld Overlay is different with that from the balance cooling.

AMTmetalTech Unique Duplex Stainless Steel Powder D for Super Cavitation & Corrosion Resist High Speed or Regular Laser Cladding & PTA Plasma Weld Overlay can effectively control the Duplex microstructure rate in the coating to achieve the best cavitation resistance.

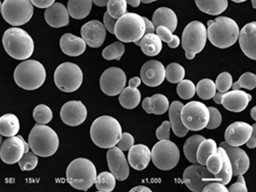

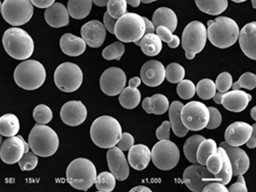

AMTmetalTech Super Cavitation and High Corrosion Resist Unique Duplex Stainless Steel Powder DSL size 20-63um is for High Speed Laser Cladding. DL size 53-150um is for Regular Laser Cladding or PTA Plasma weld overlay.

Type | (%)Chemical Composition | ||||||||

DSL | Fe | Cr+Ni | Mo+B+Zr | C+N | Mn | Si | O | P | S |

Balance | 30-38 | 2.0-6.0 | 0.03-0.70 | ≤1.0 | ≤1.0 | ≤0.15 | ≤0.03 | ≤0.015 | |

2. AMTmetalTech Unique Duplex Stainless Steel Powder D for Super Cavitation and Corrosion Resist Laser Cladding or PTA Plasma Weld Overlay Applications

Laser Clad Hydro Turbine Laser Clad Turbine Runner Laser Clad Turbine Runner

PTA Clad Propeller Blade Plasma Clad Impeller Runner PTA Plasma Clad Pump Body

AMTmetalTech Super Cavitation and High Corrosion Resist Unique Duplex Stainless Steel Powder D is Suitable for High Speed or Regular Laser and PTA Plasma weld overlay Hydro Turbine Blade, Steam Turbine Blade, Hydro Turbine Runner, Hydro Propeller Blade, Hydro or Steam Impeller, Hydro or Steam Pump Body etc.

3. AMTmetalTech Unique Duplex Stainless Steel Powder D for Super Cavitation and Corrosion Resist Laser Cladding or PTA Plasma Weld Overlay Packaging

The standard packaging for Unique Duplex Stainless Steel Powder D of Super Cavitation and High Corrosion Resist High Speed or Regular Laser Cladding and PTA Plasma Weld Overlay is by plastic bottle or bag per 5 kg. We can do according to the customer requirements for other packaging.

Please send us email to export@AMTmetalTech.com about Nickel Amorphous HVAF or HVOF Tube Inside ID Spraying Fine Atomized Powder Better Corrosion risist than Hastelloy C276 / Inconel In625 / Stellite of severe Erosion, Cavitation, high temperature Abrasion resist; Duplex Stainless Steel Powder for Binder Jet Printing / Speed Laser / PTA cladding / Plasma weld overlaying Replacing Chrome Plating for Coated Cylinders / Pistons / Roller / Screw Rotors / Valve / Stirrer Blade / Hydro Turbine Runner; Tungsten Carbide Hardmetal Cemented Clad Mud Pump Liner / Pipe / Sleeve / Glass Mold and Super Wear Plate; PDC Diffusion Bonding, Diamond Bearing etc.