Top Quality World Lowest Price Agglomerated Sintered Tungsten Carbide

WC-Co Hardmetal Powders for HVOF or HVAF Thermal Spraying

1.AMTmetalTech Top Quality World Lowest Price Agglomerated Sintered Tungsten Carbide Hardmetal Powders for HVOF or HVAF Thermal Spraying

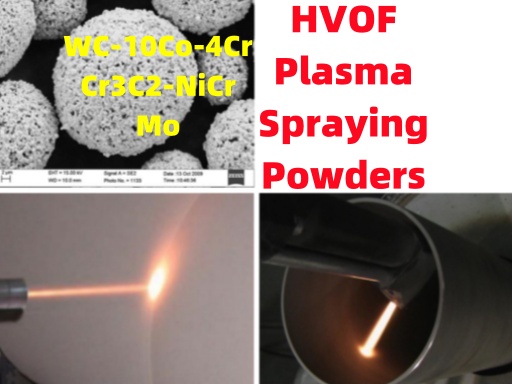

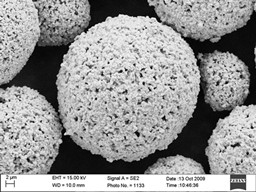

AMTmetalTech as the World Metallurgy Leader of Severe Erosion and Super Abrasion Resist, is selling our Top Quality World Lowest Price Agglomerated Sintered Tungsten Carbide Cemented Hardmetal Powders for thermal spraying to Germany, USA and Japan for over 25 years. AMTmetalTech Quality Agglomerated Sintered Tungsten Carbide Cemented Hardmetal Fine Powders for HVOF or HVAF or Plasma thermal spraying are made all from virgin raw material, with more than 24 hours milling to be very homogeneous mixed and then Spray-dried to be very round powders, Vacuum sintered to be controlled hall density, Supersonic sieved and Gas classified to be very consistent particle sizes, to make Customers getting satisfied coating.

AMTmetalTech Top Quality Agglomerated Sintered Tungsten Carbide Hardmetal HVOF or HVAF Thermal Spraying Powders grain size can be down to 0.5um. The fine size cut can be good for Tube inside coating including Crystallizers of Continuous Casting. AMTmetalTech is pleased to answer your any Metallurgy questions free of charge during thermal spraying. The specifications in the below table are our main. Please send us your inquiry if you required is not in the following table.

Name | Powder Type | Powder Size | Reference Products | Properties/Applications | ||

Metco | Praxair | Starck | ||||

AM8610 -0520 | WC-10 Co-4Cr | 5-20um | WOKA 3661FC | 558.052 | ● Excellent Flowability ● Hard chrome replacement ● Excellent abrasion and erosion resistance ● Smooth and Tough coatings with fine micro structure and high bond strength ● Useable in wet corrosion environments ● Temperature up to 500℃ ● Suitable for Paper Rolls, Gate and Ball Valves, Hydraulic Cylinders etc. | |

AM86104 -0530 | WC-10 Co-4Cr | 5-30um | WOKA 3654FC | WC731-6 | 556.059 558.059 | |

AM86104 -1038 | WC-10 Co-4Cr | 10-38um | WOKA 3655 | 1350VF | 557.072 558.072 | |

AM86104 -1545 | WC-10 Co-4Cr | 15-45um | WOKA 3652 | 1350VM | 557.074 558.074 | |

AM86104 -2053 | WC-10 Co-4Cr | 20-53um | WOKA 3651 | 558.088 | ||

AM8812 -0520 | WC-12Co | 5-20um | WOKA 3111FC | ● Excellent Flowability ● Tough and Dense coating with fine microstructure ● Smooth and Hard coating with High Bond Strength ● High resistance to Abrasion, Erosion and Sliding Wear ● Temperature up to 500℃ ● For Paper Mill Rolls, Pump Parts, Oilfield Apparatus, Wire Drawing Equipment, Fan and Compressor Blades, Machine Parts etc. | ||

AM8812 -0530 | WC-12Co | 5-30um | WOKA 3110FC | WC727-6 | 518.059 519.059 | |

AM8812 -1038 | WC-12Co | 10-38um | WOKA 3105 WOKA 3104 | 1342VF | 518.072 519.072 | |

AM8812 -2053 | WC-12Co | 15-45um | WOKA 3102 WOKA 3103 | 1342VM | 518.074 519.074 | |

AM8812 -1546 | WC-12Co | 20-53um | WOKA 3101 | 518.088 519.088 | ||

AM8317 -1038 | WC-17Co | 5-30um | WOKA 3204 | WC729-5 | 526.059 | ● High Toughness and Ductility, High Fretting resistance ● Not for wet corrosion environments ● Temperature up to 500℃ ● Suitable for Crushing Rolls, Extrusion Dies etc |

AM8317 -0531 | WC-17Co | 10-38um | WOKA 3205 | 1343VF | 526.062 | |

AM8317 -1545 | WC-17Co | 15-45um | WOKA 3202 WOKA 3203 | 1343VM | 526.074 | |

AM8812N -0530 | WC-12Ni | 5-30um | WOKA 3408 WOKA 3404 | 547.059 | ● Good Resist to hammers, fretting, abrasion and sliding wear ● More corrosion-resistant and tougher than WC-Co, but lower hardness ● Temperature up to 500℃ ● Suitable for Valves, Oil Field and Radioactive environments etc. | |

AM8812N -1545 | WC-12Ni | 15-45um | WOKA 3402 WOKA 3403 | 1310VF | 547.074 | |

AM8812N -2053 | WC-12Ni | 20-53um | WOKA 3401 | 1310VM | 547.088 | |

AMTmetalTech is no way affiliated with the original equipment manufacturers (OEM) mentioned. All trademark listed herein are not of OEM's origin. References to the OEM's part numbers are for your convenience only.

2.AMTmetalTech Top Quality World Lowest Price Agglomerated Sintered Tungsten Carbide Hardmetal Powders for HVOF or HVAF Thermal Spraying Application

AMTmetalTech Top Quality Agglomerated Sintered Tungsten Carbide Hardmetal Powders are widely for producing super Abrasive or Wear, Erosion Resistant coatings by HVOF or HVAF, Plasma Thermal Spraying, which for Turbine Blades, Wire Drawing Equipment, Fans and Compressor Blades, Pumps, Valves, Pistons, Paper Rolls etc. in Aerospace, Petroleum, Metallurgical, Machinery, Transportation, Power Plant and Chemical industries.

HVOF Spraying Screw Rotors Thermal Spraying Cylinders HVAF Spraying Valve Balls

Thermal Spraying Pistons Thermal Spraying Rollers Wire Drawing Cones

3.AMTmetalTech Top Quality World Lowest Price Agglomerated Sintered Tungsten Carbide Hardmetal Powders for HVOF or HVAF Thermal Spraying Packaging

The standard packaging is by plastic bottle per 5kg. We can do the other packaging according to the customer requirements.

Please send us email to export@AMTmetalTech.com about HDH Hydride-dehydride Titanium Ti64 Powder Sintered Forge Superior than HIP Hot Isostatic Pressing, Gas or Water Atomized Additive Manufacturing Powder Bed Fusion / MIM / Binder Jet 3D Printing Cobalt / Vehicle or Car Part, Nickel Aluminum Alloy NiAlMo Catalyst / Inconel In625 / Stellite / MCrAlY / CoNiCrAlY / NiCoCrAlY / Ti 6Al 4V / Duplex Stainless Steel & 316L or Agglomerated Sintered WC-10Co-4Cr / WC-12Co / Cr3C2-NiCr / Molybdenum Spherical Powder for HVAF / HVOF Thermal or Cold Spraying and Speed Laser Cladding or PTA Clad Weld Overlay Elbow, FerroTiC for Brake Disc, Tungsten Carbide Brazing Rope, Hafnium Wires / Rods for Plasma Cutting from Crystal Iodide Hafnium Bar, Tantalum Ta & Niobium Nb for Alloy Melting, Amorphous Fine Powder Tube Inside ID Spraying replacing Chrome Plating for severe Erosion Cavitation high temperature abrasion resist of Cylinders / Pistons / Roller / Screw Rotors / Valve / Stirrer Blade / Hydro Turbine Runner; Hardmetal Cemented Clad Mud Pump Liner / Pipe / Sleeve / Glass Mold / Tile / Super Wear Plate; PDC Diffusion Bonding, Diamond Bearing etc.