Better Resistance of High Temperature Erosion Abrasion

ID Weld Overlay or Thermal Sprayed and Ground Pipe/Elbow at Thinner Coating

1. AMTmetalTech Better Resistance of High Temperature Erosion Abrasion ID Weld Overlay or Thermal Sprayed and Ground Pipe/Elbows at Thinner Coating Description

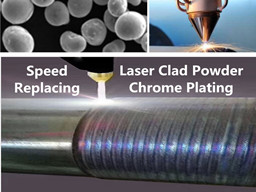

AMTmetalTech is equipped with the each several production lines of Steel Tube ID Laser or PTA Plasma Cladding, Pipe ID Thermal Spraying, Pipe ID Grinding, Pipe Fitting or Elbow ID Cladding etc.

Long Tube ID Thermal Spraying Pipe ID Grinding High Speed Laser Cladding

AMTmetalTech can use Laser / PTA Powder Weld Overlay, TIG Wire Cladding, HVOF / HVAF / Plasma Powder Thermal Spraying processes etc. for the Coating.

AMTmetalTech can coat with Duplex Stainless Steel, Nickel / Copper / Titanium Alloys, Tungsten Carbide / Chrome Carbide, Ferro / Nickel Alloy Amorphous + NanoCrystalline, Chrome Oxide / Ytteria Stablized Zirconia etc.

Cladding Process | Coating Chemical | Coating Thickness | Bonding Strength | Tube or Part Length | ID Min. |

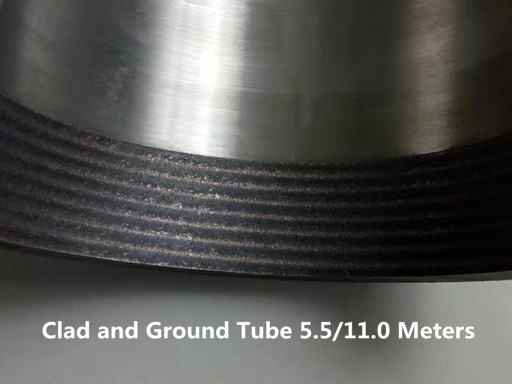

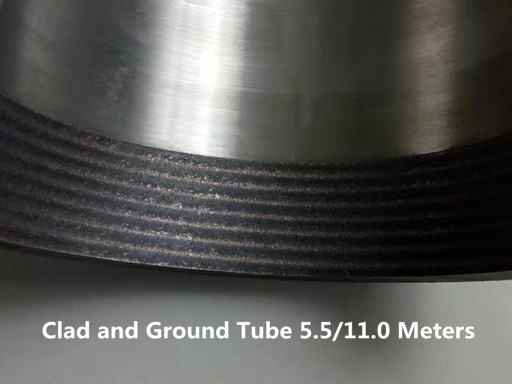

A. Laser or PTA + Powder, TIG+Wire | A1. In625, In718, NiCrBSi | 0.5-5.0mm | ≥500MPa | 5.5 or 11.0 Meters or to the Customer | 80mm |

B. HVOF / HVAF / Plasma Powder Thermal Spraying | B1. WC-10Co-4Cr, Cr3C2-NiCr | 0.3-0.5mm | 50-100MPa | 5.5 or 11.0 Meters or to the Customer | 80mm |

2. AMTmetalTech Better Resistance of High Temperature Erosion Abrasion ID Weld Overlay or Thermal Sprayed and Ground Pipe/Elbows at Thinner Coating Applications

AMTmetalTech High Temperature Erosion Abrasion Resist ID Weld Overlay or Thermal Sprayed and Ground Long Tube or Elbows are widely for the Industries of Chemical, Oil & Gas, Power etc.

Chemical Industry Oil & Gas Industry Power Industry

Please send us your inquiry by email with Tube or Part Drawings to be Coated as well as the Working Media Chemical, Temperature and Abrasion Condition, so that we can send you testing sample after you satisfied our competitive quotation.

3. AMTmetalTech Better Resistance of High Temperature Erosion Abrasion ID Weld Overlay or Thermal Sprayed and Ground Long Tube or Typical Parts at Thinner Coating

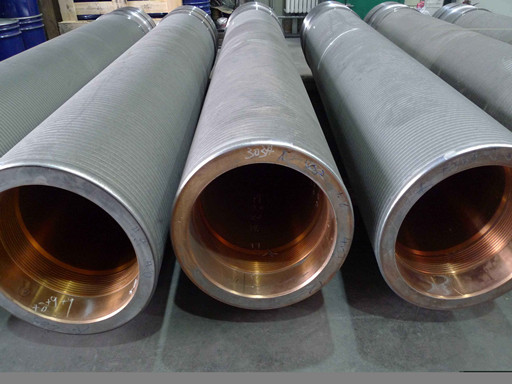

AMTmetalTech Typical Clad Parts include Nickel Alloy / Tungsten Carbide ID Weld Overlay or Thermal Sprayed Steel Pipe as Clad or ID Ground Finish, Pipe Fittings and Elbows, Boiler Tubes, Screw Extrusion Barrels, various Rolls and Cylinders, Pistons, Turbines, Glass Molds, Liners etc. for Erosion, High Temperature and Abrasion Resist.

Nickel Clad 900℃ Erosion Steel Tube ID ID Clad Super Abrasion Pipe Elbow/Fittings ID Thermal Spray Coated Erosion Tube

Laser Clad 900℃ Erosion Boiler Water Tube PTA Clad 900℃ Erosion Screw Barrel Laser Clad Abrasion Corrosion Rolls/Cylinders

Please send us email about Atomized Additive Manufacturing AM / Binder Jet Printing / High Speed Steel MIM Powder / 3D Printed Part, Self-fluxing or Spray Fuse Nickel Alloy NiBSi / Inconel In625 / Stellite / MCrAlY / Ti-6Al-4V Ti64 / Stainless Steel 316L or Agglomerated Sintered Fine WC-10Co-4Cr / Chrome Carbide Cr3C2-NiCr / Molybdenum Powder for HVAF / HVOF / Flame / Plasma ID or Flash Carbide Thermal / Cold Spraying and Laser Cladding or PTA Clad Pipe / Weld Overlay Tube Elbow, Spherical Cast / Fused Tungsten Carbide Powder / Titanium Carbide Cemented TiC Sintered Hardmetal Wear Tile or Ring / Flexible Brazing Rope etc.