Additive Manufacturing AM or 3D Printing

Vacuum Gas Atomized Alloy Powders and Printed Parts

1. AMTmetalTech Quality Additive Manufacturing AM or 3D Printing Vacuum Gas Atomized Alloy Powders main type and chemical

AMTmetalTech produces Additive Manufacturing AM or 3D Printing Vacuum Gas Atomized Alloy Powders in hundreds tons annually at very competitive quality and pricing.

Type | Chemical Composition, wt% | |||||||||||||||

C | Cr | Ni | Mo | Si | Mn | S | P | Nb | Cu | V | Mg | Ti | Fe | Co | Al | |

Ti64 | 3.50-4.50 | Balance | ≤0.3 | 5.5-6.75 | ||||||||||||

Inconel 625 | ≤0.1 | 20.0-23.0 | Balance | 8.0-10.0 | ≤0.5 | ≤0.5 | ≤0.015 | ≤0.015 | 3.15-4.15 | ≤0.4 | ≤5.0 | ≤1.0 | ≤0.4 | |||

Inconel 718 | ≤0.08 | 17.0-21.0 | 50.0-55.0 | 2.8-3.3 | ≤0.35 | ≤0.35 | ≤0.01 | ≤0.01 | 4.75-5.50 | ≤0.3 | B≤0.006 | 0.65-1.15 | Balance | ≤1.0 | 0.2-0.8 | |

316L Stainless Steel | ≤0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | ≤1.00 | ≤2.00 | ≤0.03 | ≤0.045 | Balance | |||||||

17-4PH | ≤0.07 | 15.5-17.5 | 3.0-5.0 | ≤1.00 | ≤1.00 | ≤0.03 | ≤0.04 | 0.15-0.45 | 3.0-5.0 | Balance | ||||||

MS1 Tool Steel | ≤0.03 | ≤0.5 | 17.0-19.0 | 4.5-5.2 | ≤0.1 | ≤0.1 | ≤0.01 | ≤0.01 | ≤0.5 | 0.6-0.8 | Balance | 8.5-9.5 | 0.05-0.15 | |||

CoCrMo | <0.35 | 27.0-30.0 | <0.5 | 5.0-7.0 | <1.0 | <1.0 | W<0.25 | B<0.01 | N<0.25 | <0.2 | <0.1 | <0.75 | Balance | <0.1 | ||

AlSi10Mg | ≤0.05 | 9.0-11.0 | ≤0.45 | Sn≤0.01 | Pb≤0.01 | Zn≤0.1 | ≤0.1 | 0.2-0.45 | ≤0.15 | ≤0.55 | Balance | |||||

CuCrZr | 0.5-1.5 | Zr .05-.25 | Balance | |||||||||||||

AZ33 MgAlZn | Zn 2.2-3.8 | Balance | 2.6-4.2 | |||||||||||||

2. AMTmetalTech Quality Additive Manufacturing AM or 3D Printing Vacuum Gas Atomized Alloy Powders Particle Size Distribution and Oxygen content

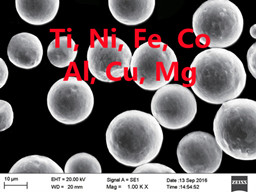

Typical Size: 4-22um, 15-45um, 15-53um, 45-105um etc. Oxygen Content: Normally ≤500PPM for Ni, Fe, Co, Cu alloys; ≤1500PPM for Ti, Al, Mg alloys. Powder Sphericity: ≥0.9

Other type and chemical, Particle Size Distribution is available as inquired.

3. AMTmetalTech Quality Additive Manufacturing AM or 3D Printing Vacuum Gas Atomized Alloy Powders Packaging

The standard packaging is 5kg per Vacuum Bag or Plastic Bottle. We can do according to the customer requirements for packaging.

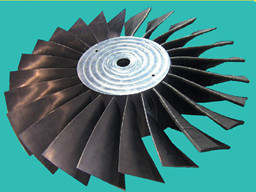

4. AMTmetalTech Quality Additive Manufacturing AM or 3D Printed Parts

AMTmetalTech Additive Manufacturing AM or 3D Printing machines include EOS M400, EOS M290, BLT S310 for SLS and SLM; Arcam Q20 for Electron Beam Melting of Max. size 400 * 400 * 400 mm3 and Accuracy 20-100um. Please send drawings for inquiry various Printed Parts.

EOS M400 for SLS and SLM EOS M290 for SLS and SLM BLT S310 for SLS and SLM

SLS Printed Steel Parts SLM Printed AlSi10Mg SLS Printed Hastelloy C276

SLM Printed Inconel 718 Electron Beam Melting In625 Electron Beam Melting Ti64

Please send us email about Atomized Additive Manufacturing AM / 3D Printing / MIM Powder / 3D Printed Part, Self-fluxing Nickel Alloy NiBSi / Hastelloy / Inconel / Stellite / MCrAlY / NiCrCoAlY / Ferro Alloy 316L or Agglomerated Sintered Fine WC / Chrome Carbide Nickel Chrome Cr3C2-NiCr Powder for HVAF / HVOF / Flame / Plasma ID or Flash Carbide thermal spraying and Laser or PTA Cladding, Spherical Cast / Fused / Monocrystalline / Macrocrystalline Tungsten Carbide Powder / Titanium Carbide TiC Wear Tile or Ring / Sintered Tungsten Carbide Cemented Hardmetal Pellet Flexible Welding Rope for Hardfacing overlaying etc.