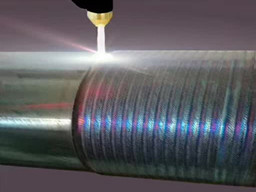

Laser or PTA Plasma Alloy Powder Cladding Machine System

including Power, Rotator, Robot or Positioner

Laser Overlaying Robot System Speed Laser Cladding System

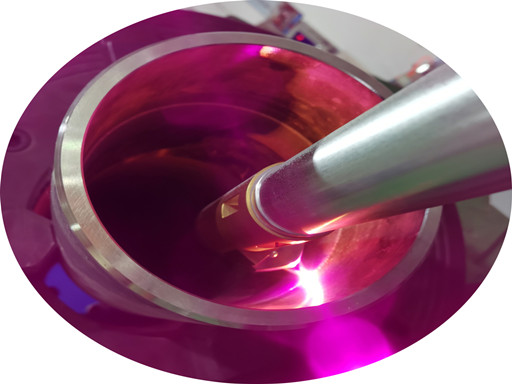

Laser Cladding Boiler Tube Tube ID Laser Cladding Laser Clad Valve Ball Laser Quenching Head

1. AMTmetalTech Alloy Powder Laser Overlaying Machine System

AMTmetalTech Laser Powder Cladding or Overlaying Machine System includes the Fiber Laser Device, Anti-vibration Laser Cladding Head, Accurate Powder Feeder, Chiller, Stable Rotator, Precision Robot or Positioner etc. Different Laser Cladding Machine can realize:

1.1 Coating thickness 0.05-1.0mm

1.2 Overlaying Efficiency 0.5-3.0m2/h

1.3 Powder Feeding 0.1-300g/min.

1.4 Powder Size 25-63um, 53-150um

1.5 Bead Width 0.6-4.0mm

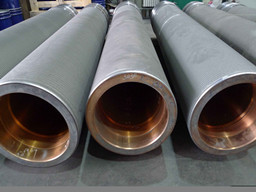

1.6 Tube ID*One Side Length, 26*300mm, 105*6000mm

1.7 Power 0.5-6.0KW

1.8 Head Speed 0.5-100.0m/min.

2. AMTmetalTech Alloy Powder PTA Plasma Overlaying Machine System

PTA Overlaying Machine System PTA Overlaying Device System

PTA Overlaying Robot PTA Plasma ID Cladding Plasma Cladding Screw Barrel ID Plasma Cladding

AMTmetalTech PTA Plasma Cladding or Overlaying Machine System includes the IGBT Plasma Power Source, Plasma Cladding Gun, Powder Feeder, Chiller, Stable Rotator, Precision Robot or Positioner etc. Different Plasma Cladding Machine can realize:

2.1 Coating thickness 0.5-5.0mm

2.2 Bead Width 4.0-50.0mm

2.3 Power Current 10-300A

2.4 Powder Size 53-150um

2.5 Tube ID* One Side Length, 50*600mm, 80*6000mm

3. AMTmetalTech Laser or PTA Plasma Overlaying Service and Applications

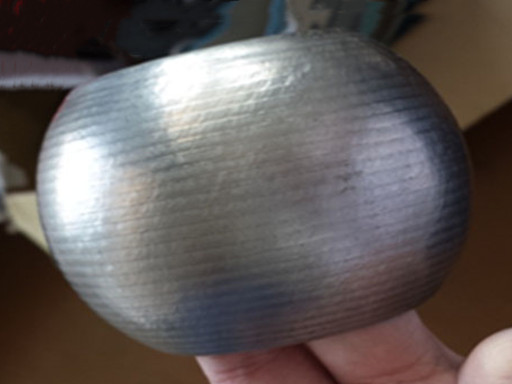

AMTmetalTech provides Alloy Powder Laser or PTA Plasma Quality Overlaying Service in various parts including Valve Balls and Seats, Boiler Tubes, Screws, Pistons, Barrels, Pumps, Rollers, Cutter, Molds, Hydro Cylinders, Tube Inside etc. for the new parts build up or re-manufacturing in Wear/Abrasion/Erosion/Temperature Resistance in Power, Mining, Steel, Cement, Oil and Gas, Sugar, Pulp and Paper, Chemical, Agriculture, Machinery industries.

Please send us email about Atomized or Spherical Densified Additive Manufacturing Titanium or Aluminum or Copper AM / 3D Printing / MIM or PM Molding / Soft Magnet Carbonyl Iron Powder, Atomizing Machine, 3D Printed Part, Self-fluxing Nickel Alloy NiCrBSi / NiBSi / Hastelloy / Inconel / Stellite / MCrAlY / NiCrCoAlY / Stainless Steel 316L / 17-4 PH / Bronze or Agglomerated Sintered WC / Chrome Carbide Nickel Chrome Cr3C2-NiCr / Molybdenum Powder for HVAF / HVOF / Flame / Plasma ID or Flash Carbide thermal spraying and Laser Cladding or PTA Clad Tube, Binderless Tungsten Carbide / Titanium Carbide TiC Cemented Hardmetal Wear Part / Seal Ring / Nozzle / Ball Valve etc.