Amorphous Nickel Spraying Powder NanoX Better Corrosion than Hastelloy,

HV700-900, 1000℃ Abrasion, 50um Airtight Replace Chrome Plating

1. Amorphous Nickel Spraying Powder of Better Corrosion than Hastelloy, HV700-900, 1000℃ Abrasion, 50um Airtight Replace Chrome Plating Description

AMTmetalTech patent Gas Atomized Powder NanoX and NanoY are Nickel Self-fluxing Alloy improved from Hastelloy. Both are of uniform Amorphous+Nanocrystalline microstructure, with sizes 8-25, 15-45, 2-10, 25-90um etc. Fine powder can be for Tube Inside ID coating and the finish is very smooth. After metal thermal spraying in some lower heat input than Tungsten Carbide powder and with rapid cooling, the Coating can achieve higher Amorphous rate than in the powder. The NanoX coating can have porosity lower than 0.1%, deposition rate about 50% and the coating of thickness over 50um can be no need sealing and very economic for replace chrome plating. The NanoY coating can have porosity about 1% and the deposition rate about 70%.

NanoX and NanoY Powder Sizes Choice:

1.1 Size 8-25um is for various Guns of Axial or Center Direction powder feeding.

1.2 Size 15-45um is for various Guns of Radial or Vertical Direction powder feeding.

1.3 Size 2-10um is for Guns of Inside Diameter ID under 80mm tube inside coating.

1.4 Size 25-90um is for Plasma or Detonation Spraying.

2.Amorphous Nickel Spraying Powder of Better Corrosion than Hastelloy, HV700-900, 1000℃ Abrasion, 50um Airtight Replace Chrome Plating Properties

2.1 better corrosion resist than Hastelloy C276 or Inconel625 and Stellite6 or 12, can resist pure Acid or pure Alkali.

2.2 high hardness HV700-900 and have very good Abrasion resist.

2.3 can resist high temperature up to 1000℃.

2.4 good bonding strength.

2.5 can be used for HVAF or HVOF thermal spraying, Plasma or Detonation Spraying, act as Bond Coat or Tube Inside ID coating.

Type | Chemical Composition(%) | ||||||||||||||

Nano Y, Nano X | Ni | Cr | Al | Cu | Co | Nb +Ti | Si | Mo | B | P | Mn | Fe | C | Zr | Ce+ La |

Balance | 15- 45 | 0.00 1-18 | 0.00 1-15 | 0.0 01- 10 | 0.0 01- 10 | 0.0 1- 12 | 0.0 01- 10 | 0.0 01- 6 | 0.0 01- 8 | 0.0 01- 5 | 0.0 1- 15 | ≤ 0.3 | 0.0 7-3 | 0.01 1-1 | |

For further increase the abrasion or wear resistance, NanoYW=NanoY+15% (WC/10Co/4Cr), NanoXW=NanoX+15%(WC/10Co/4Cr)

Thermal Spraying Process Suggestions:

A1 Choose suitable parameters by trial specimens before the salt fog test formal specimen. The microstructure of the trial specimens has to have the uniform lamina without big round particles and oxidizing. The hardness of the trial specimens has to be not too high.

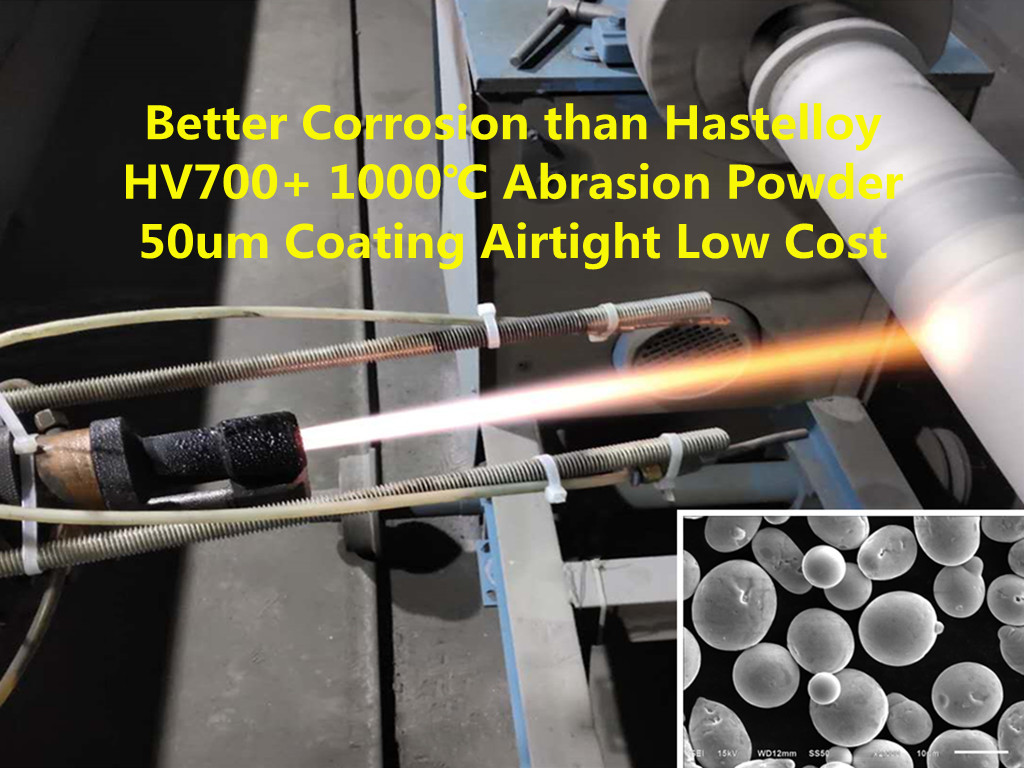

A2 Use pressure air 50mm top from the coating for quick cooling out of the nozzles front and back of the spraying gun during spraying as above picture.

A3 Choose Short Barrel. Short Spraying Distance. Low Flame Temperature. Keep the base metal temperature under 100℃. Each pass thickness under 8um. When act as bond coat, the follow-up coating need quick cooling. Grinding or polishing the specimen to be metallic shiny before corrosion or abrasion test.

3.Amorphous Nickel Spraying Powder of Better Corrosion than Hastelloy, HV700-900, 1000℃ Abrasion, 50um Airtight Replace Chrome Plating Applications

HVOF Spraying Screw Rotors Thermal Spraying Cylinders HVAF Spraying Valve Balls

Thermal Spraying Drive Pipes Thermal Spraying Pulp Rolls Thermal Spraying Pistons

AMTmetalTech Patent powder NanoX is suitable for the Severe Erosion, High Cavitation, High Abrasion or Wear, High Temperature Resist Sucker Rods, Screw Rotors, Cylinders, Valves, Drive Pipes, Pulp Rolls, Pistons, Hydro Turbine Blades, Seawater Erosion and replace chrome plating much longer life than Hastelloy / Inconel / Stellite etc.

4. Amorphous Nickel Spraying Powder of Better Corrosion than Hastelloy, HV700-900, 1000℃ Abrasion, 50um Airtight Replace Chrome Plating Packaging

The standard packaging is by vacuum bag per 5 or 10 kg. We can do according to the customer requirements for packaging.

5. AMTmetalTech Nano Spraying Powder Size Suggestion for Guns

AMTmetalTech Nano Spraying Powder Size Suggestion for Guns | ||||

Spraying Type | Powder Feeding | Nano Powder Size | Suitable Spraying Guns | Nano Powder Competitors |

ID-Coating | ID≤80mm | 2-10um | NanoHVOF, | No Other Superfine Metal Powder |

ID≥80mm | 8-25um | AK-ID HVAF, NanoHVOF, ID-NOVA/HVOF etc. | No Other Fine Amorphous Powder | |

OD-HVAF, Top Layer or Bond Coat | All | 8-25um | Kermetico, UniqueCoat etc. | |

OD-HVOF, Top Layer or Bond Coat | Axial/Center Feeding | 8-25um | DJ2700, GTV-K2, JetKote etc. | |

Radial/Vertical Feeding | 15-45um | JP5000/8000, CastoJet, SUPERCote etc. | Liquidmetal, Nanosteel, No other Nickel Amorphous Spraying Powder in the world | |

OD-Detonation Spraying, Top Layer or Bond Coat | All | 25-90um | D-Gun, Plasma etc. | |

Please send us email about Nickel Amorphous HVAF or HVOF Tube Inside ID Spraying Fine Atomized Powder Better Corrosion risist than Hastelloy C276 / Inconel 625 / Stellite of severe Erosion, Cavitation, high temperature Abrasion resist Replacing Nickel Clad Tube; Ferro Powder for high speed Laser / PTA cladding / Plasma overlaying Replacing Chrome Plating for Cylinders / Pistons / Screw Rotors / Valve Balls / Stirrer Blade / Hydro Turbine; Tungsten Carbide Hardmetal Cemented Clad Mud Pump Liner / Tube / Sleeve / Glass Mold and Super Wear Plates for Brick Mould; PDC Diffusion Bonding, Diamond Bearing and Brazing etc.