Patent Nickel Self-flux Powder NanoN for Speed Laser or PTA Cladding + Fuse of Corrosion as Hastelloy, High Abrasion, Temperature 1000℃

1.Patent NanoN Nickel Powder for Speed Laser or PTA Cladding+Fuse of Corrosion as Hastelloy, High Abrasion, Temperature 1000℃ Description

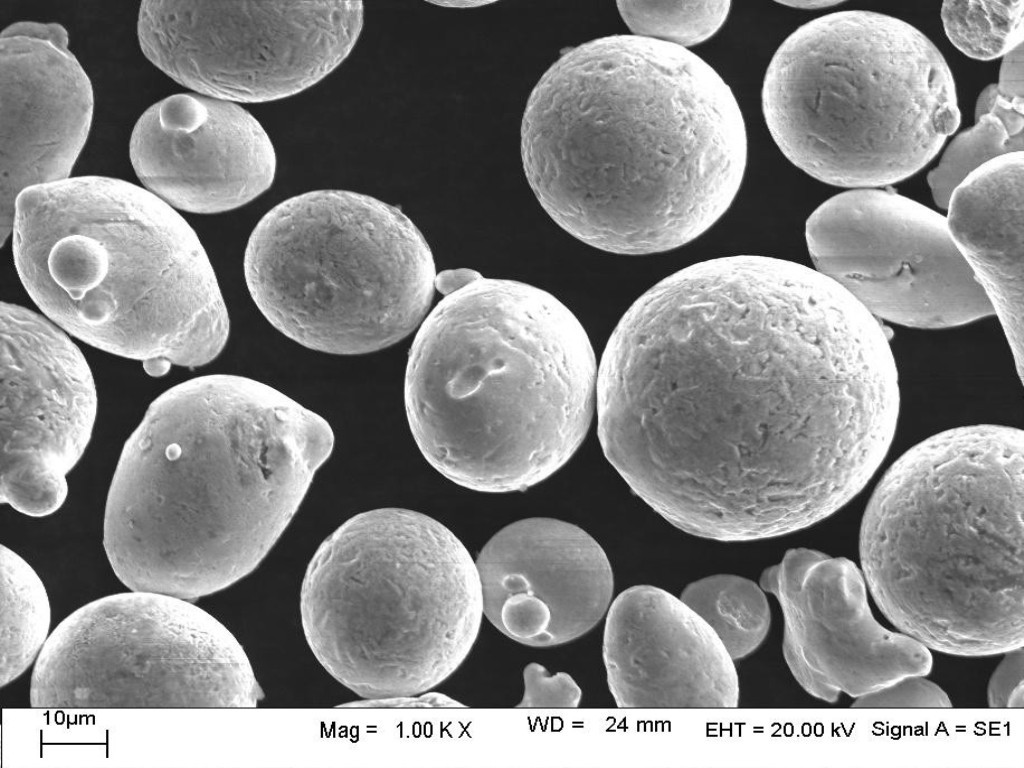

AMTmetalTech Gas Atomized Patent super Nickel self-fluxing alloy NanoNF and NanoN series powders have the similar Corrosion resistance as HastelloyC276 and Inconel625 or Stellite. NanoNF and NanoN can resist the Pure Acid or Alkali corrosion and the high Temperature up to 1000℃

The NanoNF coating hardness is HV700-900 and very good Abrasion Resist. Coating crack is normal if without preheat. Preheat 250℃ or Fuse can avoid the coating cracking. Although the Fuse is additional, while can benefit to the cladding at super high speed without caring cracks and take over caring the roughness from the cladding

The NanoN coating hardness is about HRC40 and good Abrasion Resist. The coating can be no cracking without Preheat or Fuse.

NanoNFH size 15-53um is suitable for the High Speed Laser Cladding+Fuse. NanoNFL size 45-150um is for regular Laser Cladding+Fuse. NanoNFPTA size 45-150um is for PTA Plasma Cladding+Fuse.

Type | Chemical Composition(%) | |||||||||||||

NanoNFH, NanoNFL, NanoNFPTA, NanoNL, NanoNPTA |

Ni |

Cr |

Cu |

Co | Nb+ Ti |

Si |

Mo |

B |

P |

Mn |

Fe |

C |

Zr | Ce+ La |

Balance |

15- 45 |

0.00 1-15 |

0.00 1-10 |

0.00 1-10 | 0.0 1- 12 |

0.00 1-10 | 0.0 01- 6 | 0.0 01- 8 | 0.0 01- 5 | 0.0 1- 15 |

≤ 0.3 |

0.0 7-3 |

0.01 1-1 | |

NanoNL size 45-150um is for regular Laser Cladding. NanoNPTA size 45-150um is for PTA Plasma Cladding.

PTA Plasma swing cladding can achieve fine coating thickness down to 0.4mm.

2.Patent NanoN Nickel Powder for Speed Laser or PTA Cladding+Fuse of Corrosion as Hastelloy, High Abrasion, Temperature 1000℃ Applications

AMTmetalTech Patent Nickel self-fluxing Alloy Powder NanoNF and NanoN are suitable for the Severe Corrosion as Hastelloy or Inconel or Stellite, High Abrasion and High Temperature 1000℃ Resist by High Speed Laser Cladding+Fuse Cylinders, Drive Pipes, Pulp Rolls, Pistons, or Regular Laser Cladding Spectacle Pipes and Glass Molds, or PTA Plasma Swing Cladding+Fuse replacing Chrome Plating and Long Tube Inside Coating etc.

Speed Laser + Fuse Pulp Rolls Cylinders and Drive Pipes Speed Laser + Fuse Pistons

Tube Inside Laser Cladding Laser Cladding Glass Mould Long Tube Inside PTA Cladding

3. Patent NanoN Nickel Powder for Speed Laser or PTA Cladding+Fuse of Corrosion as Hastelloy, High Abrasion, Temperature 1000℃ Packagings

The standard packaging is by plastic bottle per 5kg. We can do the other packaging according to the customer requirements.

Please send us email about Nickel Amorphous HVAF or HVOF Tube Inside ID Spraying Fine Atomized Powder Better Corrosion risist than Hastelloy C276 / Inconel 625 / Stellite of severe Erosion, Cavitation, high temperature Abrasion resist Replacing Nickel Clad Tube; Ferro Powder for high speed Laser / PTA cladding / Plasma overlaying Replacing Chrome Plating for Cylinders / Pistons / Screw Rotors / Valve Balls / Stirrer Blade / Hydro Turbine; Tungsten Carbide Hardmetal Cemented Clad Mud Pump Liner / Tube / Sleeve / Glass Mold and Super Wear Plates for Brick Mould; PDC Diffusion Bonding, Diamond Bearing and Brazing etc.