Super Fine Powder NanoX of Better Corrosion than Hastelloy 1000℃ Abrasion

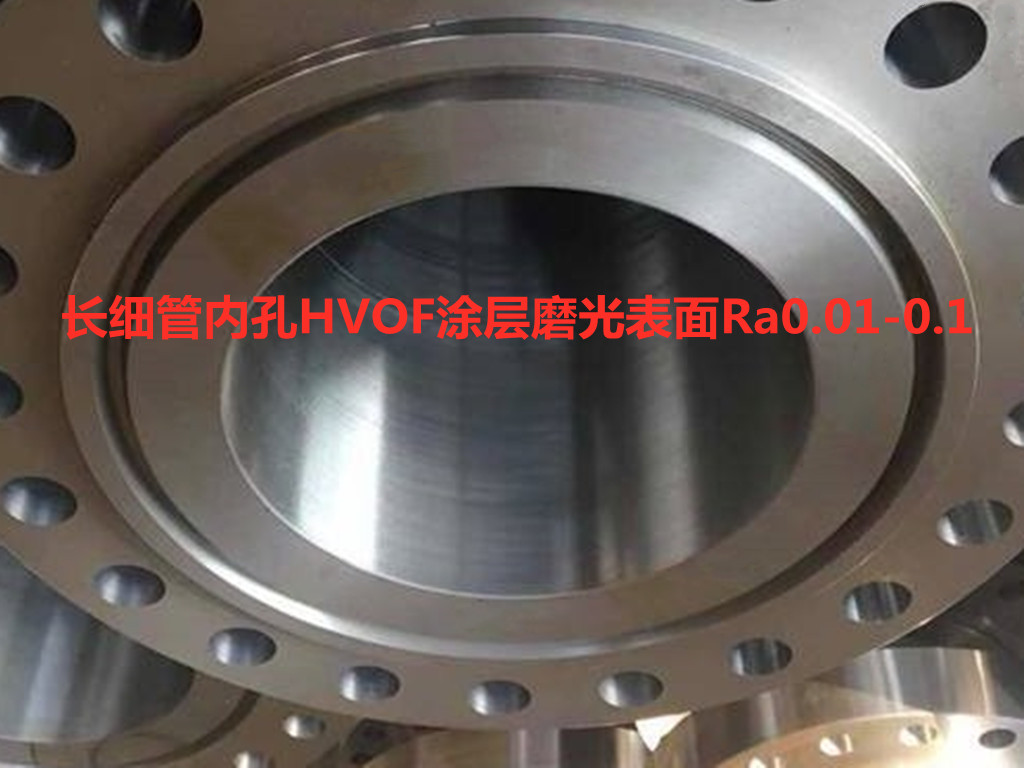

for Small ID HVOF Spraying, Coated Ground Tube

1. AMTmetalTech Patent Amorphous + Nanocrystalline Super Fine Powder NanoX of Better Corrosion than Hastelloy 1000℃ Abrasion for Small ID HVOF Spraying

Name | Powder Type | Powder Size | Coating Properties | HVAF or HVOF Applications |

NanoA | Ferro Amorphous + Nanocrystalline | 2-10um | Better corrosion resist than 316L. Good Erosion except Strong Acid or Alkali. Good Abrasion Resist, High Hardness HV700-900. Temperature Resist under 500℃. Low Cost. | ID under 80mm. |

8-25um | ID above 80mm or HVAF Flash Ferro Amorphous Powder. | |||

NanoX | Nickel Amorphous + Nanocrystalline | 2-10um | Better corrosion resist than Hastelloy C276 and In625. Super Erosion and Good Abrasion Resist even for pure Acid or Alkali. High Hardness HV700-900. Temperature Resist up to 1000℃. | ID under 80mm. |

8-25um | ID above 80mm or HVAF Flash Hard Hastelloy. |

AMTmetalTech quantity produces Patent gas atomized Amorphous + Nanocrystalline Ferro powder NanoA for tube Inside ID HVOF or HVAF thermal spraying coating is better corrosion resist than 316L, can resist various erosion except strong acid and alkali, and anti-temperature to 400℃.

AMTmetalTech Patent gas atomized Amorphous + Nanocrystalline Nickel alloy powder NanoX for tube Inside ID HVOF or HVAF thermal spraying coating is better corrosion than Hastelloy C276 and In625, can resist pure acid and alkali, anti-temperature up to 1000℃ replacing Nickel Clad Tube.

The coating hardness of both NanoA and NanoX is HV700-900.

Super Fine powder 2-10um is for spraying ID max. 80mm. 8-25um powder is for spraying ID above 80mm.

The coating is very Smooth at roughness Ra under 3um. The cost is competitive.

2. AMTmetalTech Long Small ID HVOF Sprayed and Ground Tube of Better Corrosion than Hastelloy 1000℃ Abrasion Resist Replace Nickel Clad Tube

AMTmetalTech the world top quality equipment for long small tube Inside ID HVOF spraying can make the smallest Tube Inside diameter ID 60mm, the longest tube 4 meters. The Tube Inside roughness after Sraying and Grinding can be Ra 0.01-0.1um.

Please send us email about Amorphous HVAF or HVOF Tube Inside ID and Flash Carbide Spraying Fine Atomized Powder replacing Chrome Plating or Nickel Clad Tube; Nickel Alloy powder more wear resist than Hastelloy C276 / Inconel 625 / Stellite of severe corrosion, erosion, cavitation, high temperature, abrasion resist and Ferro Powder for high speed Laser / PTA cladding / Plasma overlaying and Fuse for Cylinders / Pistons / Screw Rotors / Valve Balls / Stirrers / Hydro Turbine / Glass Mold; Tungsten Carbide Hardmetal Cemented Clad Mud Pump Liner / Tube / Sleeve and Super Wear Plates for Brick Mould; PDC Diffusion Bonding, Diamond Bearing and Brazing etc.