Super Abrasion Resist Tungsten Cemented Carbide Hardmetal Braze Clad

Patent Quick Assembly Plate, Stirring Blade and Mud Pump Liners

1.AMTmetalTech Super Abrasion Resist Tungsten Cemented Carbide Hardmetal Braze Clad Patent Design Quick Assembly Plate

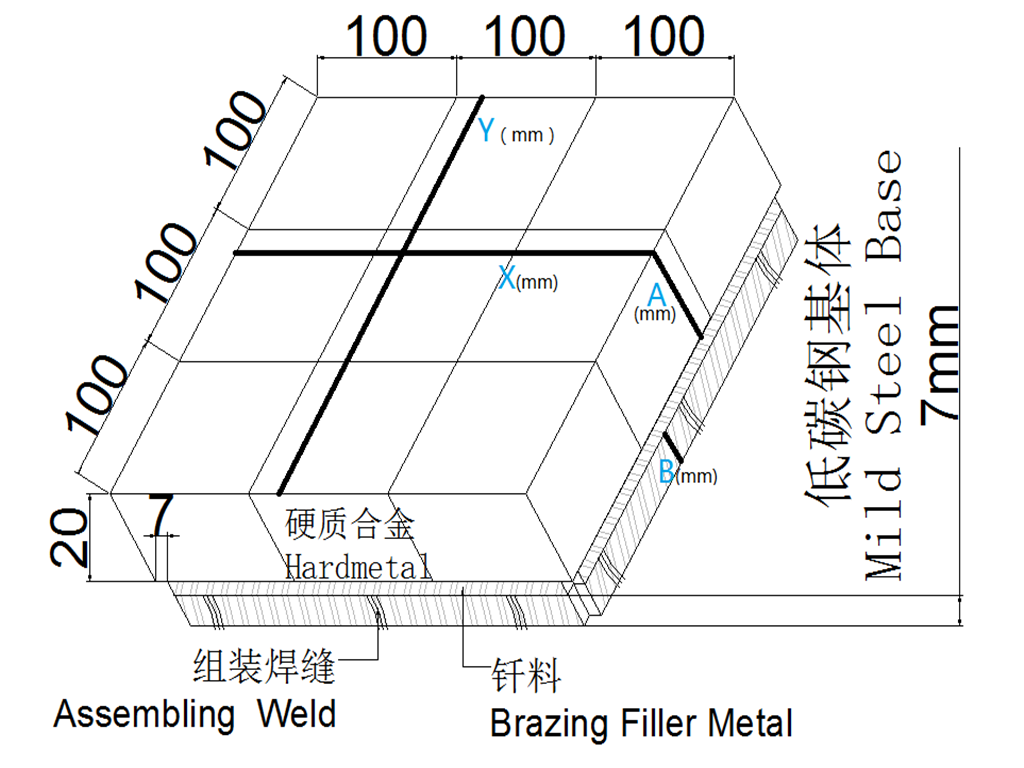

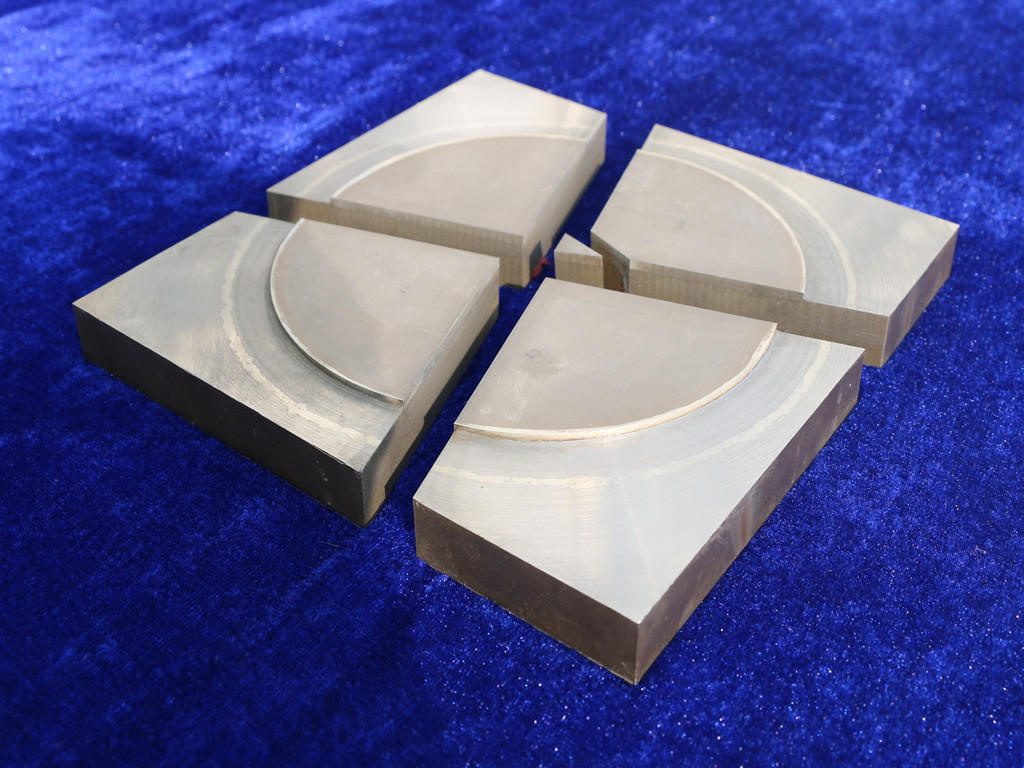

AMTmetalTech Super Abrasion or Wear Resist Tungsten Cemented Carbide Hardmetal Braze Clad patent design Quick Assembly Plate is made up of the cemented carbide braze bonded with steel base, which bonding rate and strength are high enough. The steel base makes the cemented carbide clad wear plate and Brick Mold very good strength as well as good enough abrasion resistance.

Typical Dimension: Length X300 * Width Y300mm; Base Thickness: B7mm; Cemented Carbide Wearing Layer Thickness: A16mm. Base Metal: Mild Steel.

AMTmetalTech Super Abrasion or Wear Resist Tungsten Cemented Carbide Hardmetal Braze Clad patent design Quick Assembly Plate are for Mining or Cement Industries, Brick Mold, Stirring Slurry Blade etc.

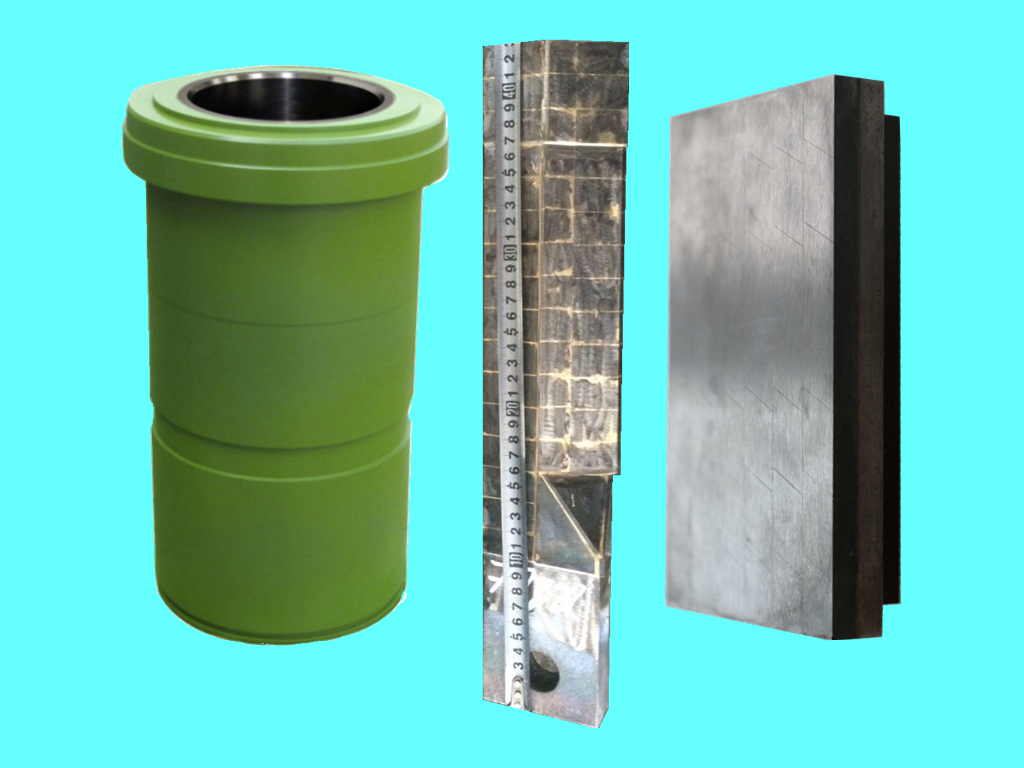

2.AMTmetalTech Super Abrasion or Wear Resist Tungsten Cemented Carbide Hardmetal Patent Design Rings Connected Clad Mud Pump Liners / Sleeves / Tubes

AMTmetalTech Super Abrasion or Wear Resist Tungsten Carbide Cemented Hardmetal Patent Design Rings Connected Clad Mud Pump Liner / Sleeves / Tubes AM-WCliner are assembled from Hardmetal Precision Rings Clad inside the steel tube or sleeve and results in high reliability. The life time of AM-WCliner can be more than 2 years.

Mud Pump Liner Material | High Chrome Cast Iron | Alumina | Ytteria Stablized Zirconia | Tungsten Carbide Hardmetal |

Life Time | Nearly Half Month | Nearly Half Year | Nearly One Year | More Than 2 Years |

Life Time | A- | A+ | AA+ | AAAAA |

Price | A- | A+ | AA+ | AAAAA |

3.AMTmetalTech Tungsten Carbide Cemented Hardmetal Typical Chemical Composition and Properties.

Types | Composition (%) | Density, g/Cm3 | Hardness, HRA | Bend Strength, N/mm2 |

AMYG6 | Co: 5.8-6.2, WC Balance | ≥14.6 | ≥91 | ≥2150 |

AMYG8 | Co: 7.8-8.2, WC Balance | ≥14.5 | ≥90 | ≥2250 |

AMYG11 | Co: 10.8-11.2, WC Balance | ≥14.1 | ≥88 | ≥2300 |

AMYG15 | Co: 14.8-15.2, WC Balance | ≥13.9 | ≥85 | ≥2500 |

AMYG20 | Co: 19.8-20.2, WC Balance | ≥13.4 | ≥80 | ≥2650 |

AMTmetalTech chemical composition of Tungsten Carbide Cemented Hardmetal can be mainly WC-Co, WC-Ni or WC-TiC-Ni etc, which is of high hardness and high Bend Strength with superior Abrasion or Wear and Erosion resistance up to 500℃. WC-Ni is nonmagnetic, high temperature resist as well.

Please send us email about Nickel Amorphous HVAF or HVOF Tube Inside ID Spraying Fine Atomized Powder Better Corrosion risist than Hastelloy C276 / Inconel 625 / Stellite of severe Erosion, Cavitation, high temperature Abrasion resist Replacing Nickel Clad Tube; Ferro Powder for high speed Laser / PTA cladding / Plasma overlaying Replacing Chrome Plating for Cylinders / Pistons / Screw Rotors / Valve Balls / Stirrer Blade / Hydro Turbine; Tungsten Carbide Hardmetal Cemented Clad Mud Pump Liner / Tube / Sleeve / Glass Mold and Super Wear Plates for Brick Mould; PDC Diffusion Bonding, Diamond Bearing and Brazing etc.