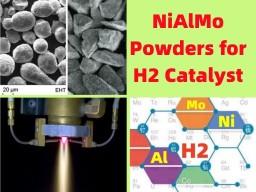

Raney Nickel NiAlMo Powders for Electrolytic Hydrogen

Cathode Mesh Plasma Spraying & Hydrogenation Catalyst

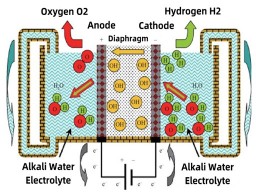

NiAlMo Powder Plasma Sprayed Nickel Mesh Alkali Water Electrolytic Hydrogen Schema

1. Raney Nickel NiAlMo Powders for Electrolytic Hydrogen Cathode Mesh Plasma Spraying & Hydrogenation Catalyst Chemical Composition

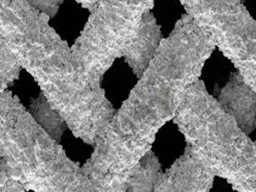

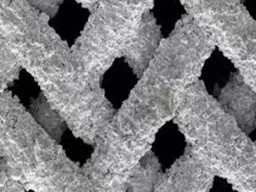

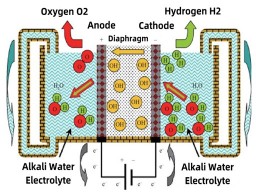

Hydrogen is completely the clean ideal energy with high efficiency. Electrolytic Alkali Water production technology, which schematic diagram as above right picture, is now quickly spreading over the world. Traditional hydrogen generators use nickel mesh as the hydrogen generation cathode. For greatly increasing the catalytic capability of generating the hydrogen on the Nickel Mesh Cathode, it is very important to create the porous catalytic coating by Plasma Thermal Spraying on the nickel mesh cathode.

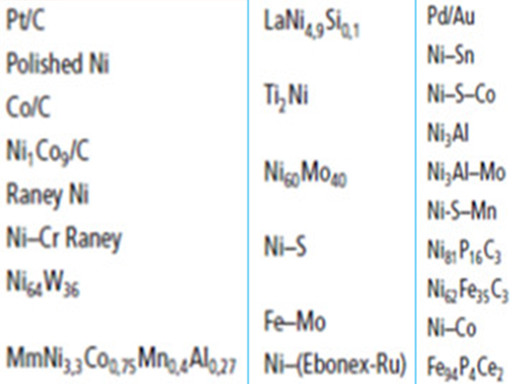

According to the scientist research from many plasma thermal spraying powders as below, the Raney Nickel NiAlMo Nickel Aluminum Molybdenum Alloy coating by plasma thermal spraying is the best to increase the catalytic capability of generating the hydrogen on the coated Nickel Mesh Cathode. This best Nickel Aluminum Molybdenum NiAlMo alloy powder requires high Aluminum content about 10-50% and high Molybdenum content about 2-40%, which is non-disclosure now.

2. AMTmetalTech Raney Nickel NiAlMo Powders for Electrolytic Hydrogen Cathode Mesh Plasma Spraying & Hydrogenation Catalyst Applications

Plasma Spraying Powders Catalyst Tested Raney Nickel NiAlMo Powders for Hydrogenation Catalyst

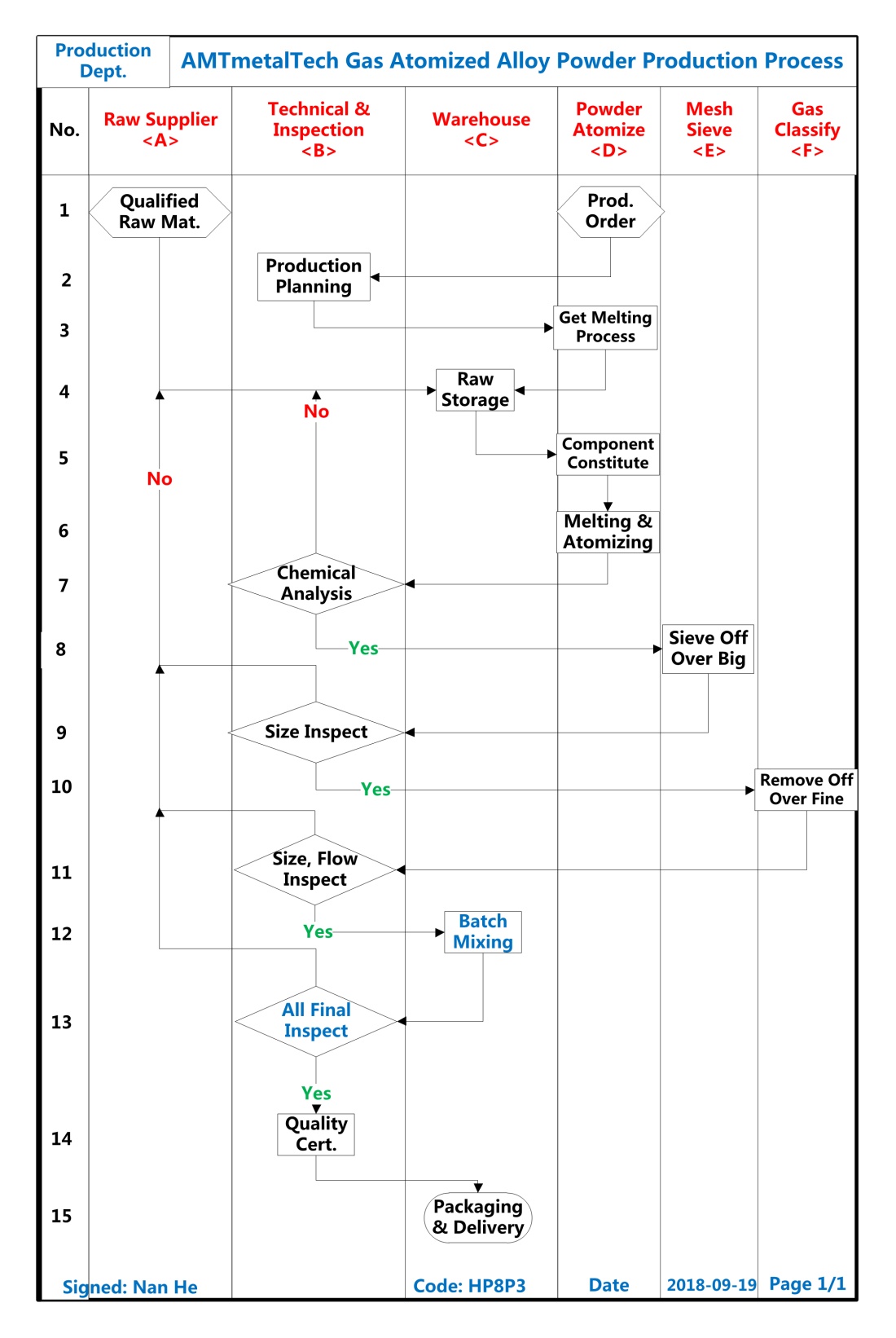

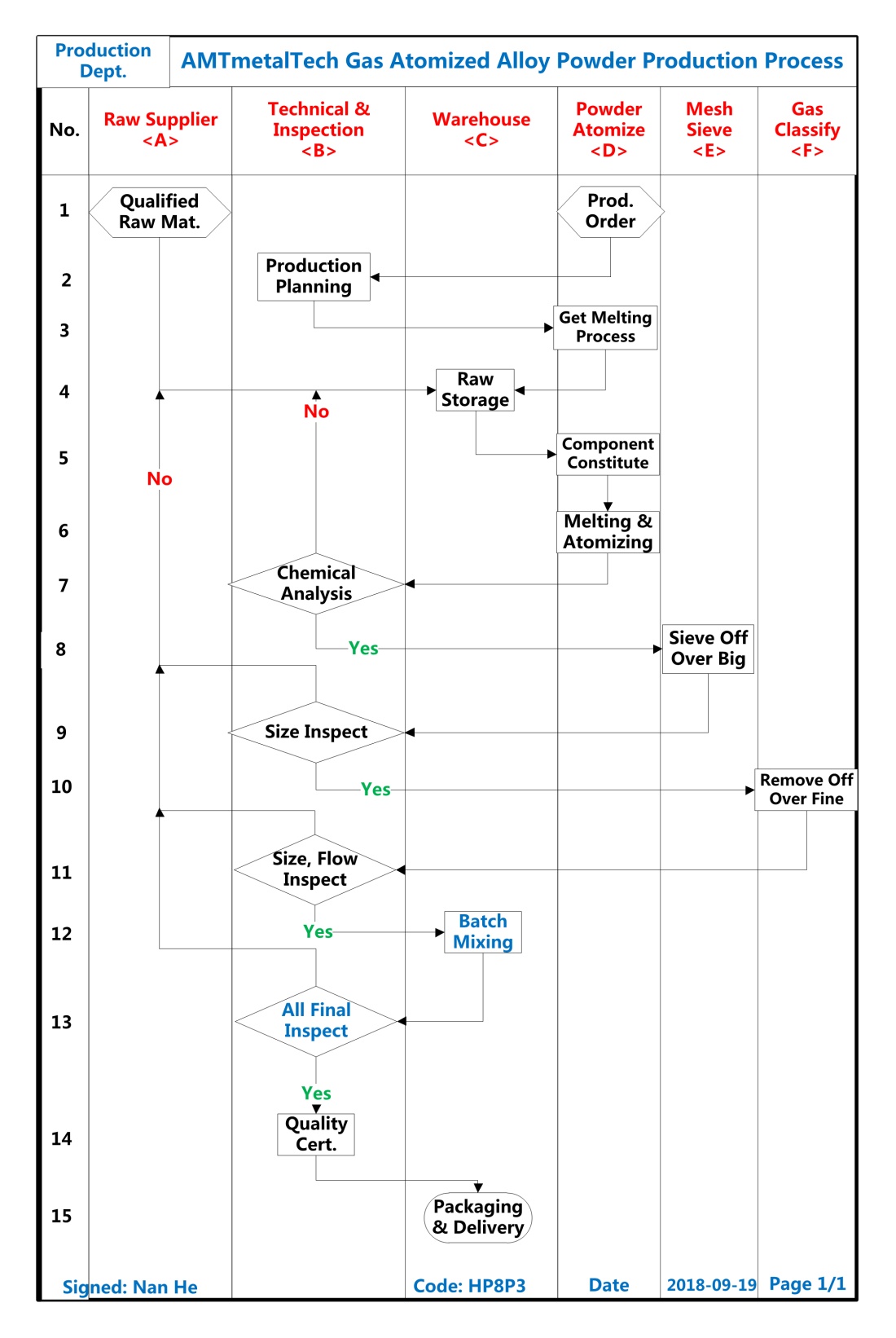

To produce the high Aluminum & high Molybdenum Nickel alloy NiAlMo powder for melting 3 metals of very big difference melting temperature with homogeneous chemical composition & low oxygen is big challenging. AMTmetalTech is producing Top Quality World Lowest Price NiAlMo high Aluminum & high Molybdenum alloy plasma thermal spraying powders by Vacuum Gas Atomize, and Raney Nickel Powders for Hydrogenation Catalyst by Melting and Crushing in many tons monthly.

The typical Raney Nickel NiAlMo powder size for Electrolytic Hydrogen Cathode Mesh Plasma Thermal Spraying is 25-63um. The typical Raney Nickel NiAlMo powder size for Hydrogenation Catalyst is 100-300 mesh, 80-150mesh, 60-100mesh, 30-80mesh etc. Other chemical composition and size of Nickel Aluminum Molybdenum Alloy Powder can be customized as well.

3. AMTmetalTech Raney Nickel NiAlMo Powders for Electrolytic Hydrogen Cathode Mesh Plasma Spraying & Hydrogenation Catalyst Packagings

Packaging of Raney Nickel NiAlMo powder for Electrolytic Hydrogen Cathode Mesh Plasma Thermal Spraying is 5kg plastic bag or bottle. Packaging of Raney Nickel NiAlMo powder for Hydrogenation Catalyst is 50kg Iron Drum or Plastic Drum with powder immersed water.

Please send us email to export@AMTmetalTech.com about HDH Hydride-dehydride Titanium Ti64 Powder Sintered Forge Superior than HIP Hot Isostatic Pressing, Gas or Water Atomized Additive Manufacturing Powder Bed Fusion / MIM / Binder Jet 3D Printing Cobalt / Vehicle or Car Part, Nickel Aluminum Alloy NiAlMo Catalyst / Inconel In625 / Stellite / MCrAlY / CoNiCrAlY / NiCoCrAlY / Ti 6Al 4V / Duplex Stainless Steel & 316L or Agglomerated Sintered WC-10Co-4Cr / WC-12Co / Cr3C2-NiCr / Molybdenum Spherical Powder for HVAF / HVOF Thermal or Cold Spraying and Speed Laser Cladding or PTA Clad Weld Overlay Elbow, FerroTiC for Brake Disc, Tungsten Carbide Brazing Rope, Hafnium Wires / Rods for Plasma Cutting from Crystal Iodide Hafnium Bar, Tantalum Ta & Niobium Nb for Alloy Melting, Amorphous Fine Powder Tube Inside ID Spraying replacing Chrome Plating for severe Erosion Cavitation high temperature abrasion resist of Cylinders / Pistons / Roller / Screw Rotors / Valve / Stirrer Blade / Hydro Turbine Runner; Hardmetal Cemented Clad Mud Pump Liner / Pipe / Sleeve / Glass Mold / Tile / Super Wear Plate; PDC Diffusion Bonding, Diamond Bearing etc.