AMTmetalTech Top Quality Super Corrosion and Temperature Resist

Inconel, Stellite Alloy, Steel Gas Atomized Powders for Surfacing

1.AMTmetalTech Top Quality Super Corrosion and Temperature Resist Inconel, Stellite Alloy, Steel Gas Atomized Surfacing Powders Character and Applications

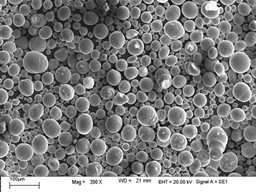

AMTmetalTech Quality Super Corrosion and Temperature Resist Hastelloy, Inconel, Stellite Alloy, MCrAlY or 316L Stainless Steel Powders Gas Atomized Powders for surfacing have good sphericity, flow ability and low oxygen, which common sizes are 15-45um, 20-53um, 45-125um and used for HVOF / HVAF / Plasma thermal spraying or Laser / PTA Plasma cladding of Severe Corrosion and High Temperature resist various parts in Oil & Gas, Chemical, Pulp, Food, Medicine, Ocean, Power industries etc.

2.AMTmetalTech Top Quality Super Corrosion and Temperature Resist Inconel, Stellite Alloy, Steel Gas Atomized Surfacing Powders Packaging

The standard packaging is by plastic bottle per 5 kg. We can do according to the customer requirements for packaging.

3.AMTmetalTech Top Quality Super Corrosion and Temperature Resist Inconel, Stellite Alloy, Steel Gas Atomized Powders Main Specifications as in the following table

Please visit www.AMTmetalTech.com/AboutUs/MCrAlY.html for more information about Top Quality World Lowest Price MCrAlY Powders for Thermal or Cold Spraying of Bontcoat or High Temperature Corrosion Resist Coating.

Type | Powder Type | Hardness | Reference | Process | Properties/Applications | ||

Metco | Praxair | Hoganas | |||||

AM-NiCoCrAlYTaHfSiRe | Ni-10Co-17.5Cr-6.5Al-0.3Y-5.5Ta-0.3Hf-1Si-1.7Re | HRC20 | HVOF, APS, VPS, LPPS | ●Temperature Oxidation Stable for Bond Coat of TBC | |||

AM-NiCrAlY | Ni-22Cr-10Al-1Y | HRC20 | Amdry 962 | Ni-164,211 | AMPERIT 413.0 | HVOF, APS, VPS, LPPS | ●Stable Temperature Oxidation for Turbine Blades Bond Coat |

AM-CoNiCrAlY | Co-32Ni-21Cr-8Al-0.6Y | HRC20 | Amdry 995C | Co-127, 211 | AMPERIT 415.0 | HVOF, APS, VPS, LPPS | ●Temperature Oxidation Stable for TBC Bond Coat |

AMinconel625 | Ni-22Cr-9Mo-4Nb-4FeCo | HRC20 | Amdry 625 | Ni-328 | In625 | HVOF, Laser, AP, PTA | ●Excellent Corrosion and Very Good Temperature resist |

AMinconel718 | Fe-52Ni-20Cr-5Nb-3MoCoTi | HRC20 | Amdry 718 | Ni-202 | In718 | HVOF, Laser, AP, PTA | ●Very Good Corrosion and Good Temperature resist |

AM-Ni8020 | Ni-20Cr | HRC20+ | Metco43VF-NS | Ni-105 | AMPERIT 251.0 | HVOF, HVAF, AP, PTA | ●Very Good Heat, Corrosion Resist and Bond Coat |

AMhastelloyC276 | Ni-15Cr-16Mo-4Fe-4WCo | HRC20 | Dia. 4276 | Ni-544 | C276 | HVOF, Laser, AP, PTA | ●Excellent Corrosion and High Temperature resist |

AMhastelloyC22 | Ni-22Cr-13Mo-4Fe-3WCo | HRC20 | HVOF, Laser, AP, PTA | ●Excellent Corrosion and Temperature Oxidation resist | |||

AM-Monel400 | Ni-30Cu | HRC20 | HVOF, Laser, AP, PTA | ●Excellent for Hydrofluoric Acid and Biological Corrosion | |||

AM-Ni1910 | Ni-19Cr-10Si | HRC50+ | Ni-430 | AMPERIT 442.9 | Braze | ●Strong, Tough, Heat Resist. Good for Nuclear. | |

AMstellite6 | Co-29Cr-5W-3Ni-1Mo-1.2C | HRC43 | Dia. 4060NS | Co-106 | 2537-00 | HVOF, Laser, AP, PTA | ● Temperature & Pressure Engine Valve, Turbine Blade |

AMstellite12 | Co-30Cr-8W-3Ni-1Mo-1.4C | HRC47 | 2541-00 | HVOF, Laser, AP, PTA | ● Temperature & Pressure Valve, Screw Rod | ||

AMtribaloy400 | Co-29Mo-9Cr-2.6Si-1.5Ni | HRC53 | Metco66F-NS | Co-109 | HB400 | HVOF, Laser, AP, PTA | ●Temperature & Corrosion Valve, Extrusion |

AMCu-10Al | Cu-10Al | HB200 | Metco445, 51NS | Cu-104 | HVOF, Laser, AP, PTA | ●Cavitation, Dry Running, Fretting Resist Pump & Guiders | |

AM316L | Fe-17Cr-12Ni-2.5Mo | HRC20 | Diamalloy1003 | Fe-101 | 316L | HVOF, Laser, AP, PTA | ●Corrosion, Heat, Impact Resist and Bond Coat |

AM431 | Fe-17Cr-2Ni-.18C | HRC50+ | Metco 42C | 431HC | HVOF, Laser, AP, PTA | ●Martensit stainless steel and wear resist, For Rollers and Flanges | |

AMTmetalTech is no way affiliated with the original equipment manufacturers (OEM) mentioned. All trademark listed herein are not of OEM's origin. References to the OEM's part numbers are for your convenience only.

Please send us email to export@AMTmetalTech.com about HDH Hydride-dehydride Titanium Ti64 Powder Sintered Forge Superior than HIP Hot Isostatic Pressing, Gas or Water Atomized Additive Manufacturing Powder Bed Fusion / MIM / Binder Jet 3D Printing Cobalt / Vehicle or Car Part, Nickel Aluminum Alloy NiAlMo Catalyst / Inconel In625 / Stellite / MCrAlY / CoNiCrAlY / NiCoCrAlY / Ti 6Al 4V / Duplex Stainless Steel & 316L or Agglomerated Sintered WC-10Co-4Cr / WC-12Co / Cr3C2-NiCr / Molybdenum Spherical Powder for HVAF / HVOF Thermal or Cold Spraying and Speed Laser Cladding or PTA Clad Weld Overlay Elbow, FerroTiC for Brake Disc, Tungsten Carbide Brazing Rope, Hafnium Wires / Rods for Plasma Cutting from Crystal Iodide Hafnium Bar, Tantalum Ta & Niobium Nb for Alloy Melting, Amorphous Fine Powder Tube Inside ID Spraying replacing Chrome Plating for severe Erosion Cavitation high temperature abrasion resist of Cylinders / Pistons / Roller / Screw Rotors / Valve / Stirrer Blade / Hydro Turbine Runner; Hardmetal Cemented Clad Mud Pump Liner / Pipe / Sleeve / Glass Mold / Tile / Super Wear Plate; PDC Diffusion Bonding, Diamond Bearing etc.